Procon Guide

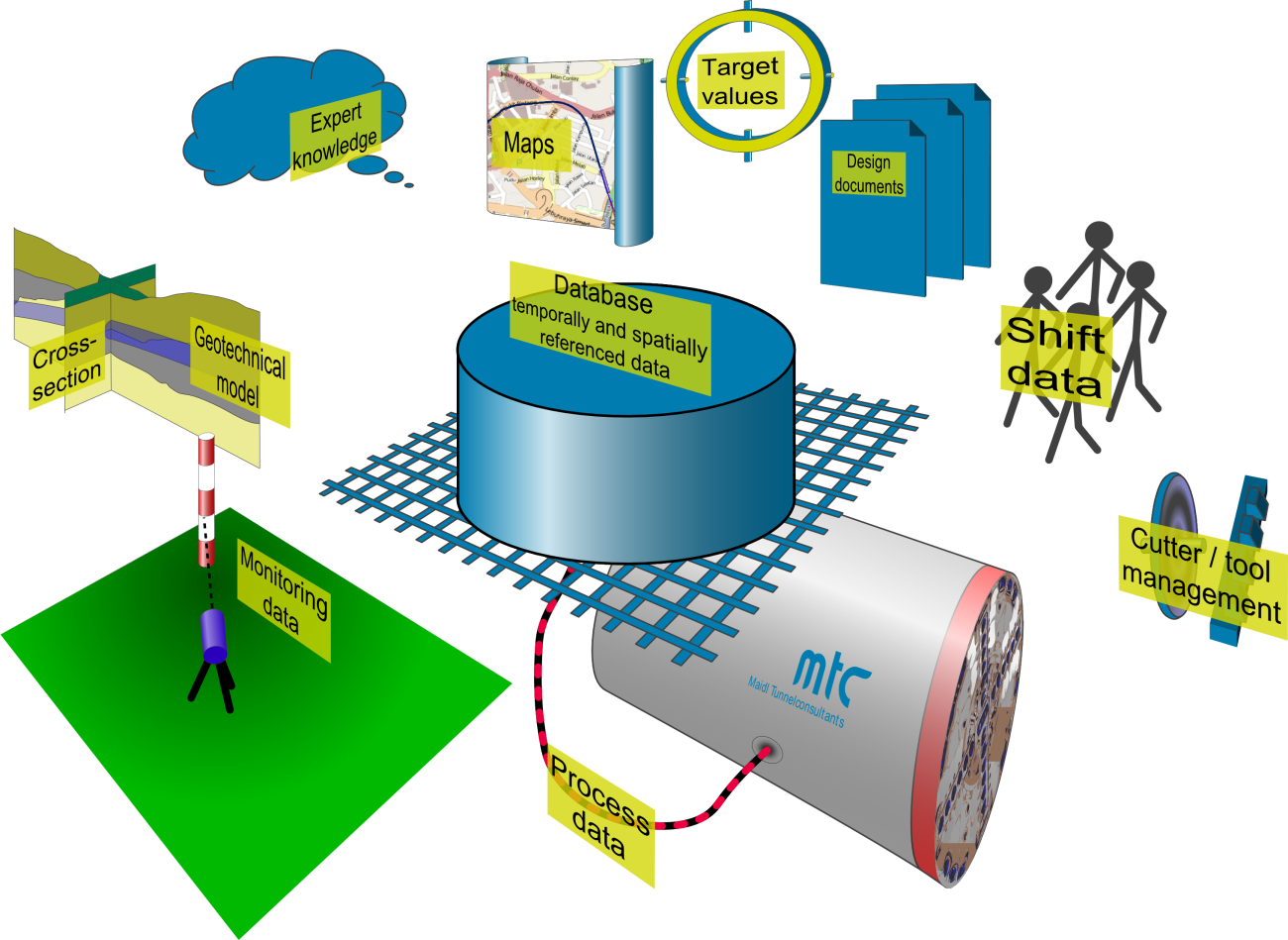

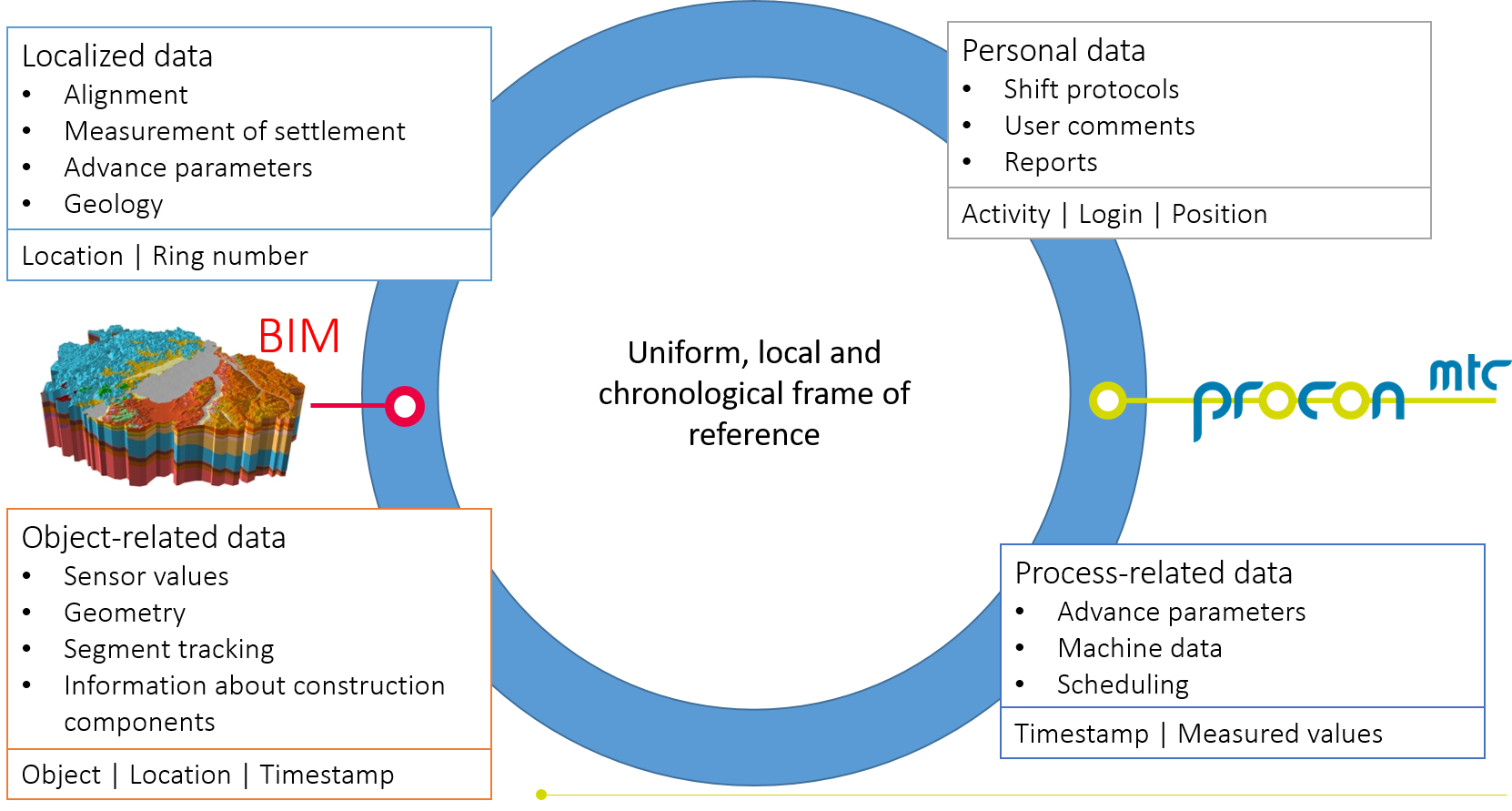

PROCON II is a software for the

technical controlling of mechanized tunnel drives. A

professional management system for the efficient recording,

analysis and visualization of data. The foundation for your

knowledge management in mechanized tunneling projects. It aims to

visualize time-dependent, location-dependent and object-dependent

data in an intuitive and meaningful way. The figure below shows

the various sources of data and information that can be

integrated, visualized and analyzed in PROCON II.

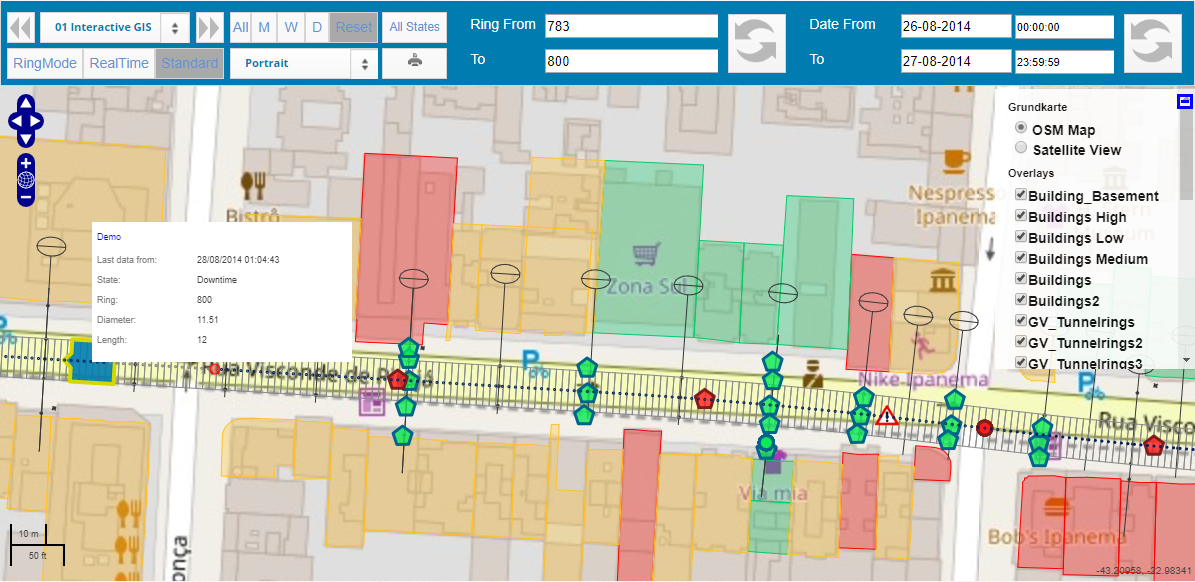

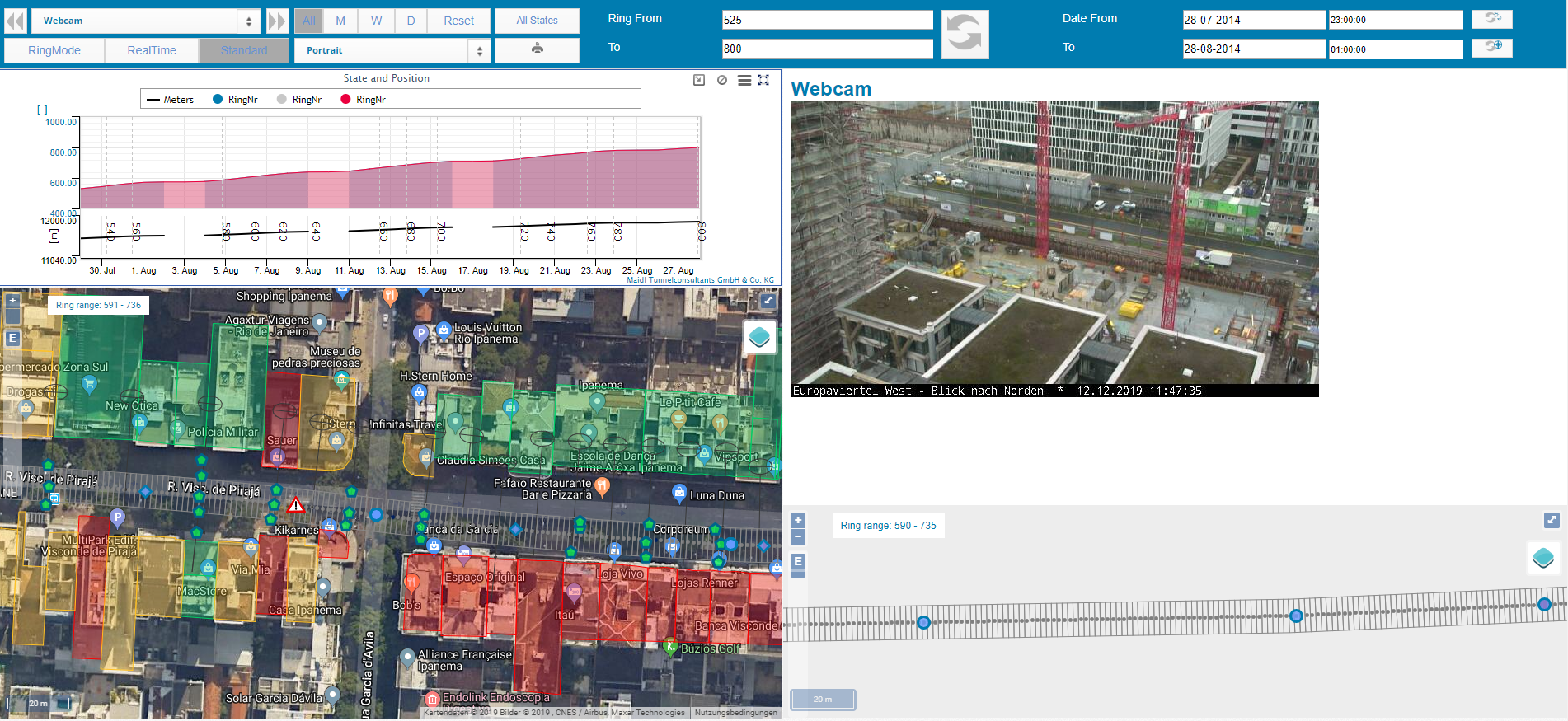

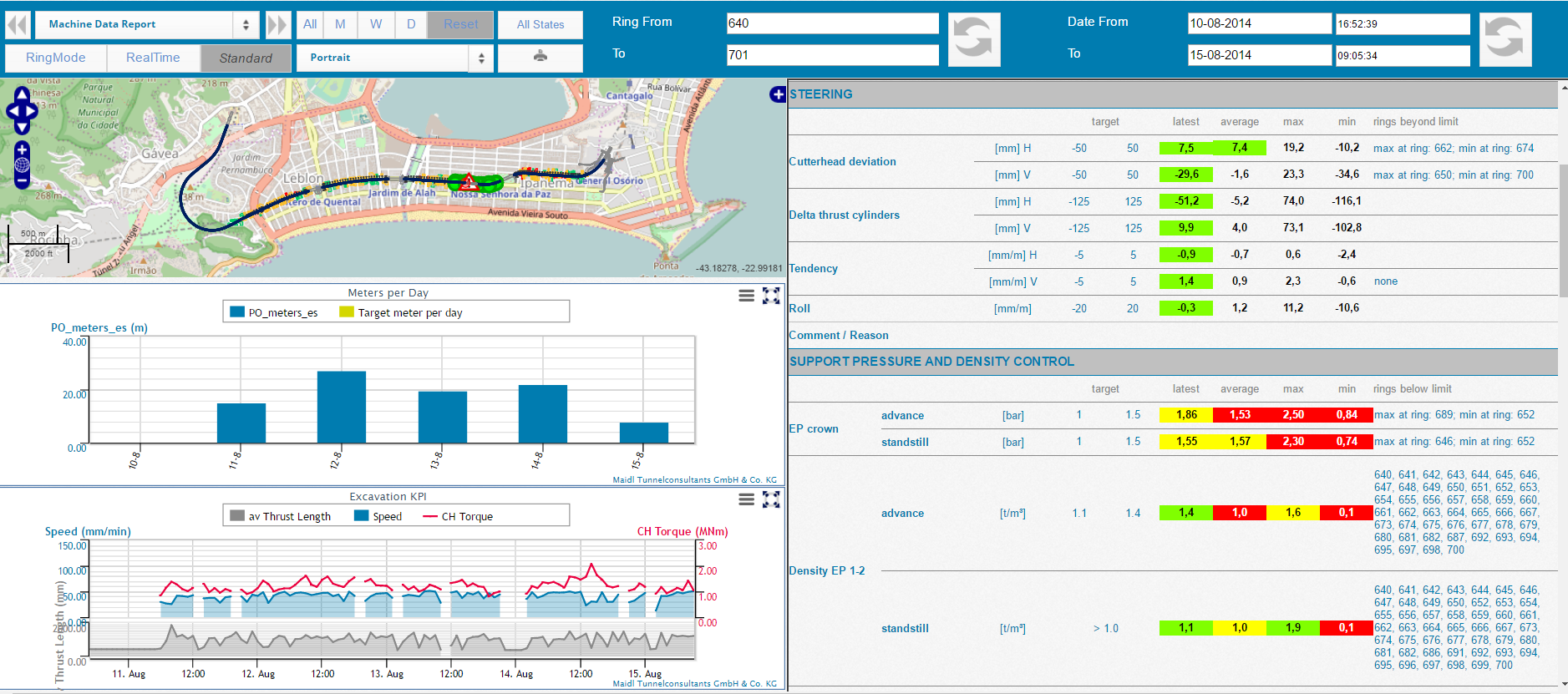

PROCON II is based on the latest

software technology. Thus, your vast process data are

transformed into visual information. Take advantage of the

affordable possibilities of geographical information systems

(GIS) and link them to your interactive charts. With the generic

chart and dashboard configurator, you can visualize all of the

relevant information tailored to your specific needs and follow

your project live with your web browser.

PROCON II is a web application that is hosted on a

secure and highly availabile cloud system. On the client side,

access to PROCON II is managed by means of SSL encrypted

communication via the HTTPS protocol and an additional access

control layer using personal logins per user. Beside the

installation of a client certificate for the encrypted

communication, no further installation efforts are required on

the client's computer. A special version with an optimized

visualization for mobile devices is optionally available.

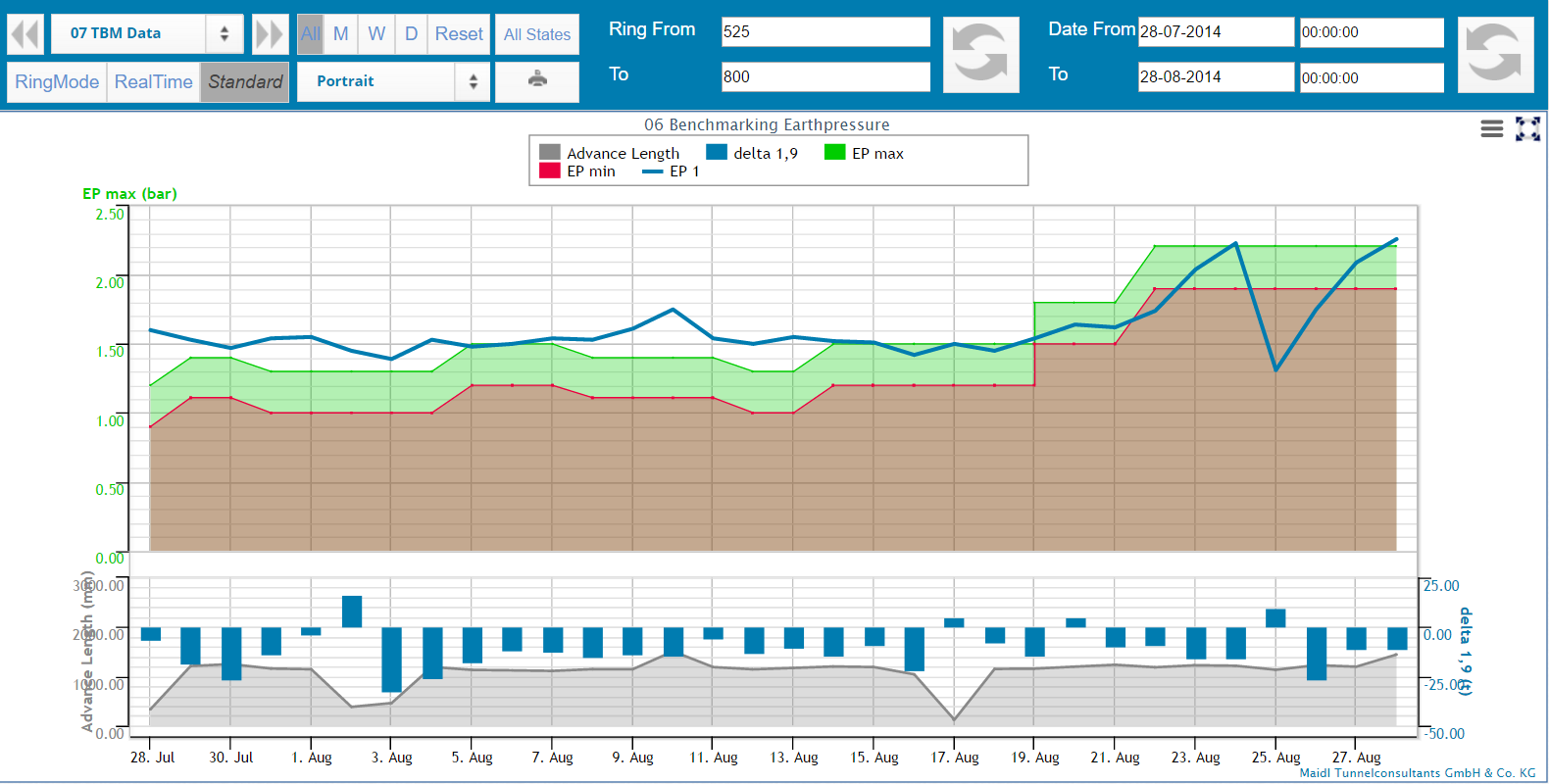

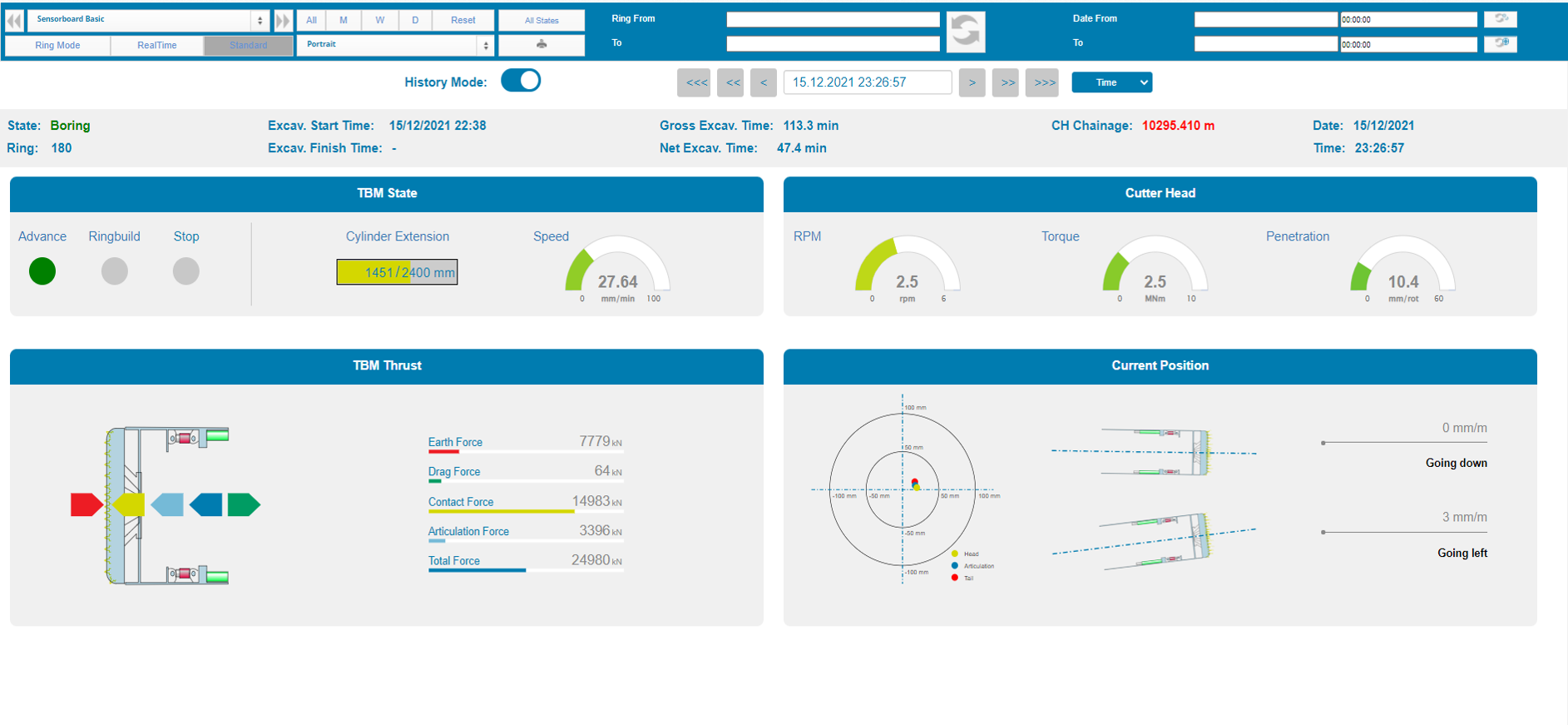

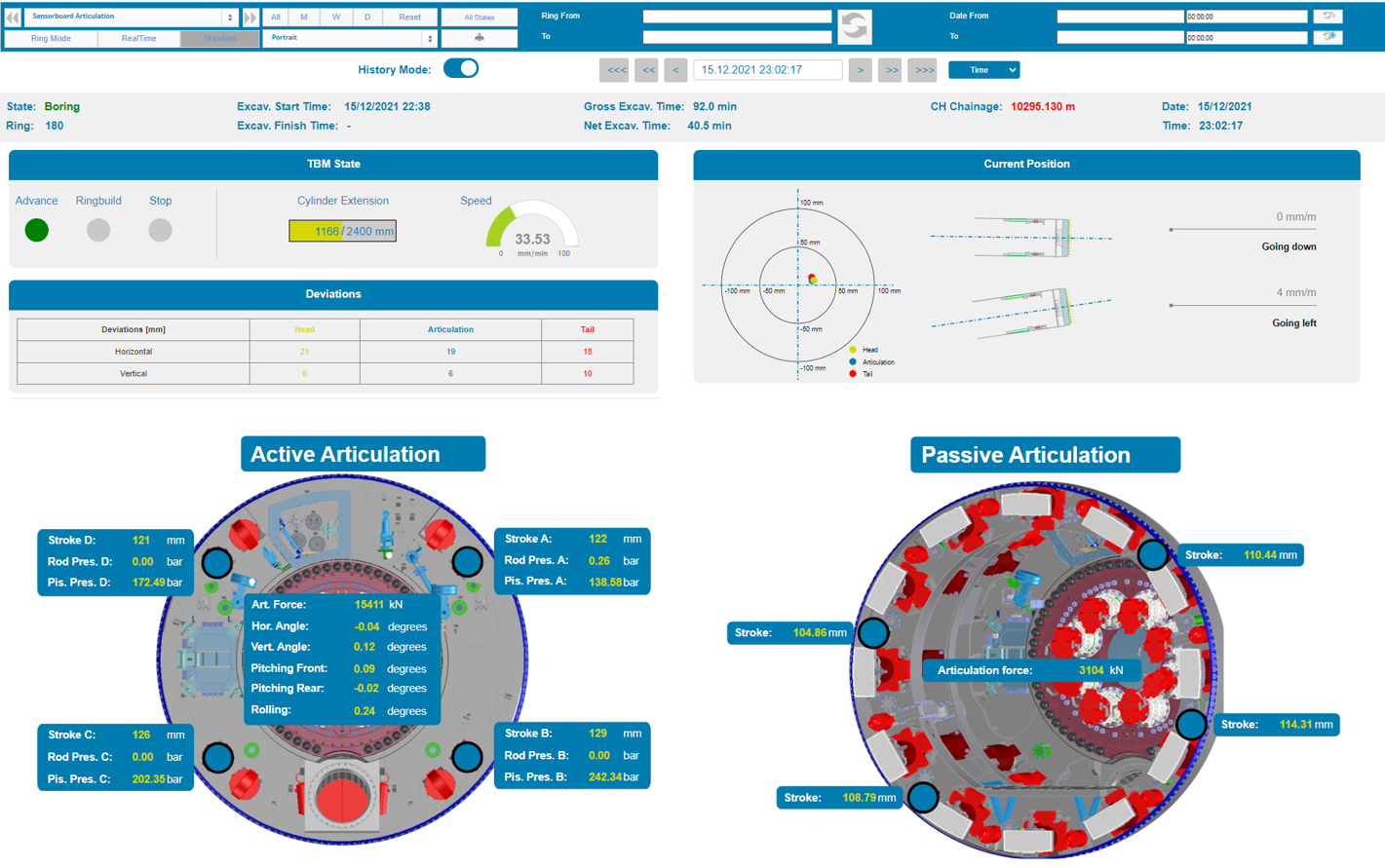

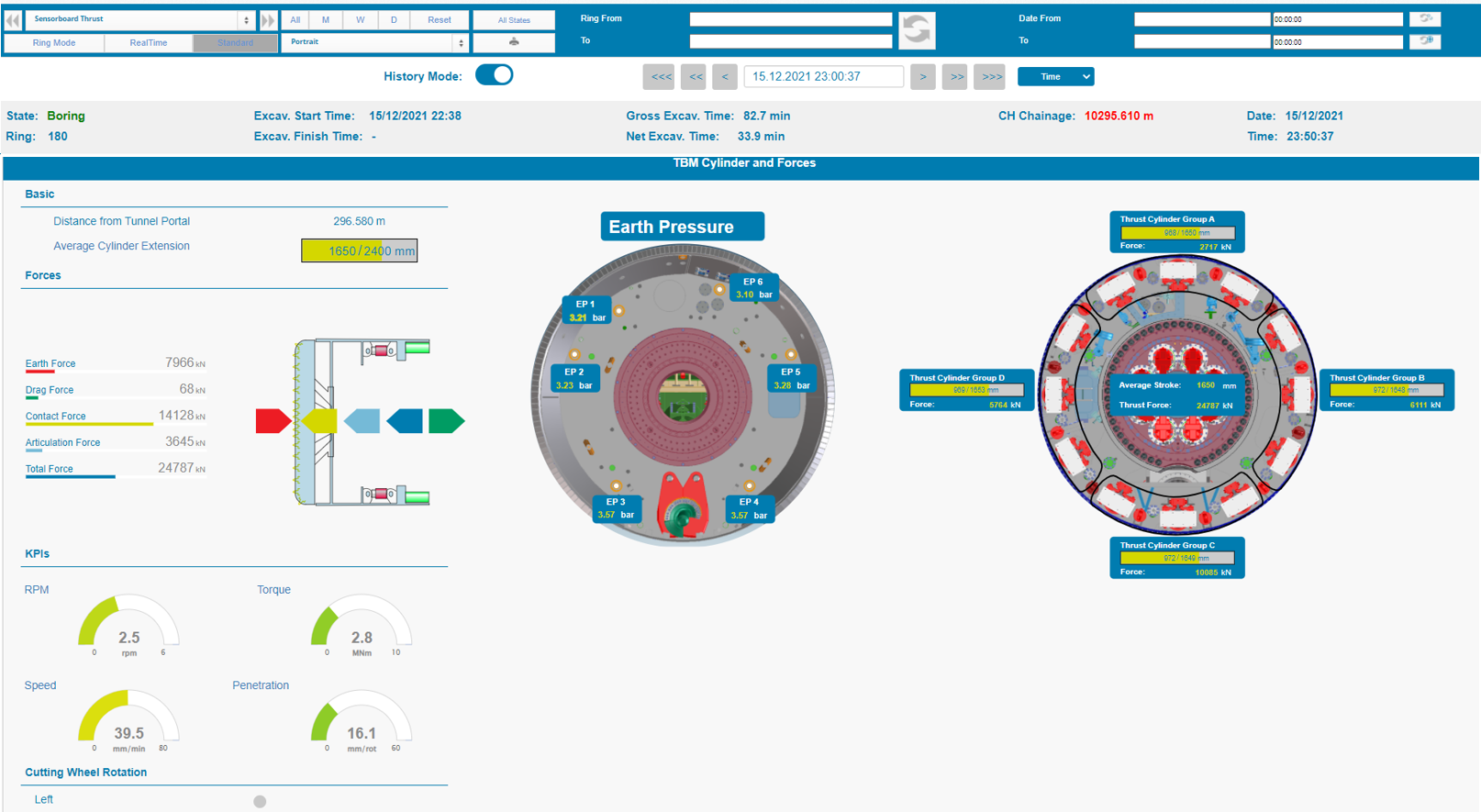

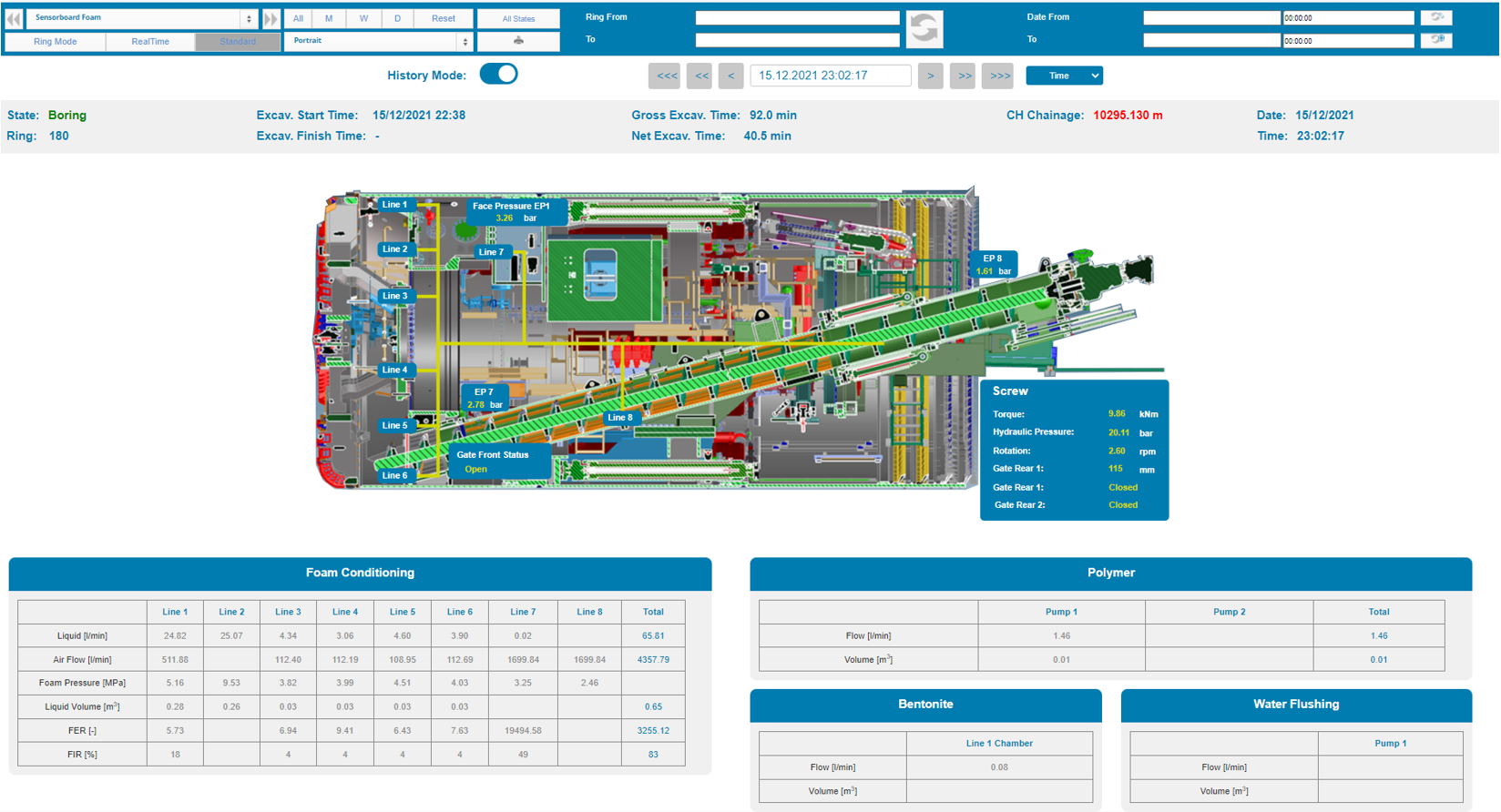

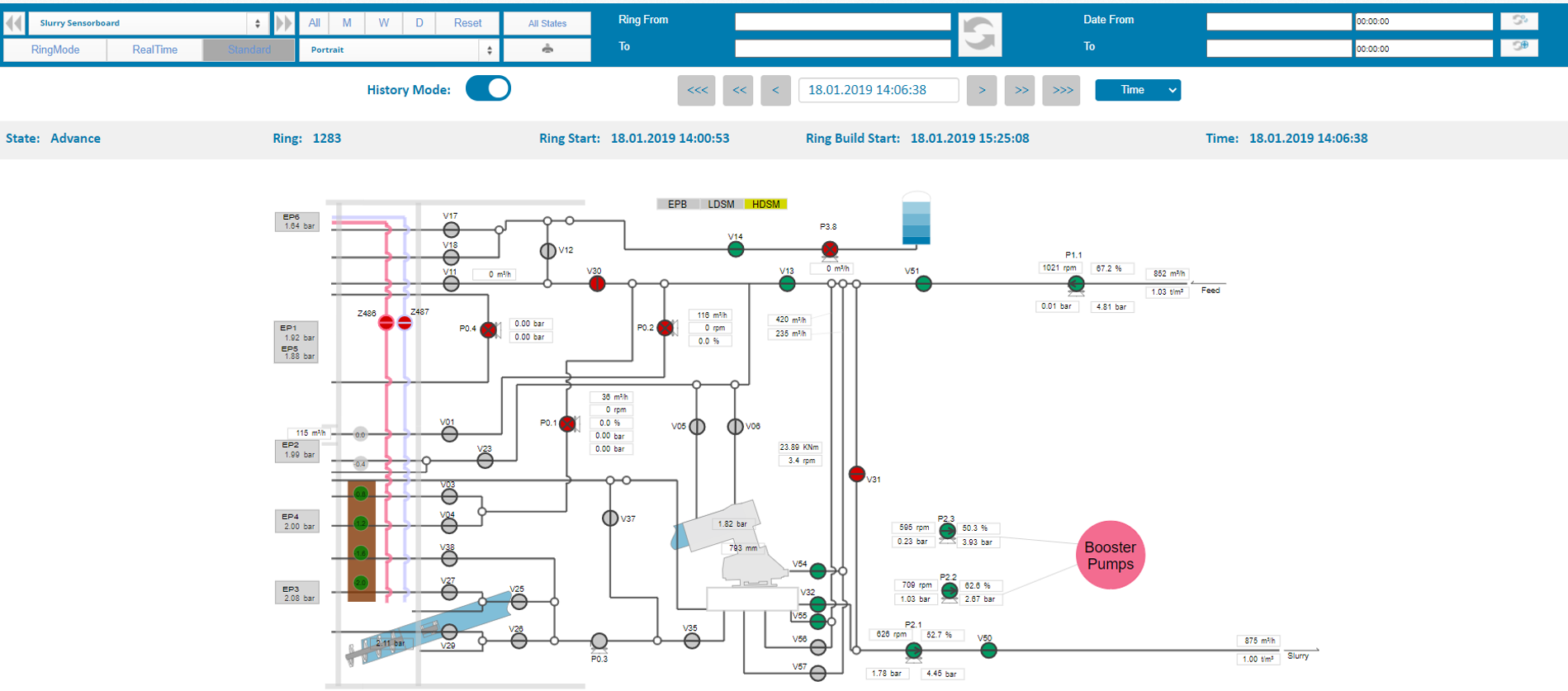

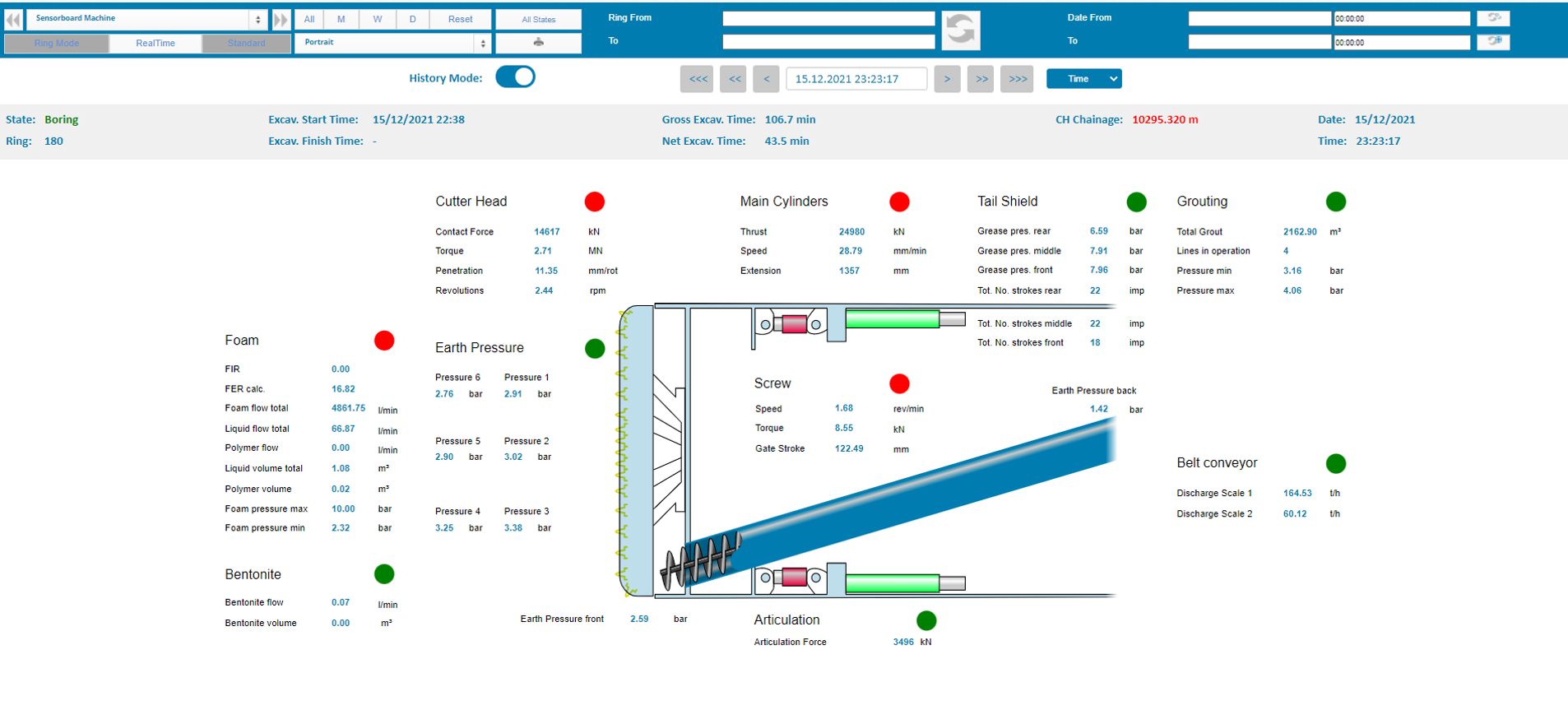

The modular design of the software allows to freely configure

the system according to the specific requirements of each

project. Beside the visualization of both real-time and

historical machine data, further information and data can be

integrated to PROCON II. Target values from the design process

can be directly compared to actual measurements. The manifold of

different visualization options can be conveniently arranged on

dashboards and can also be used to create printed reports.

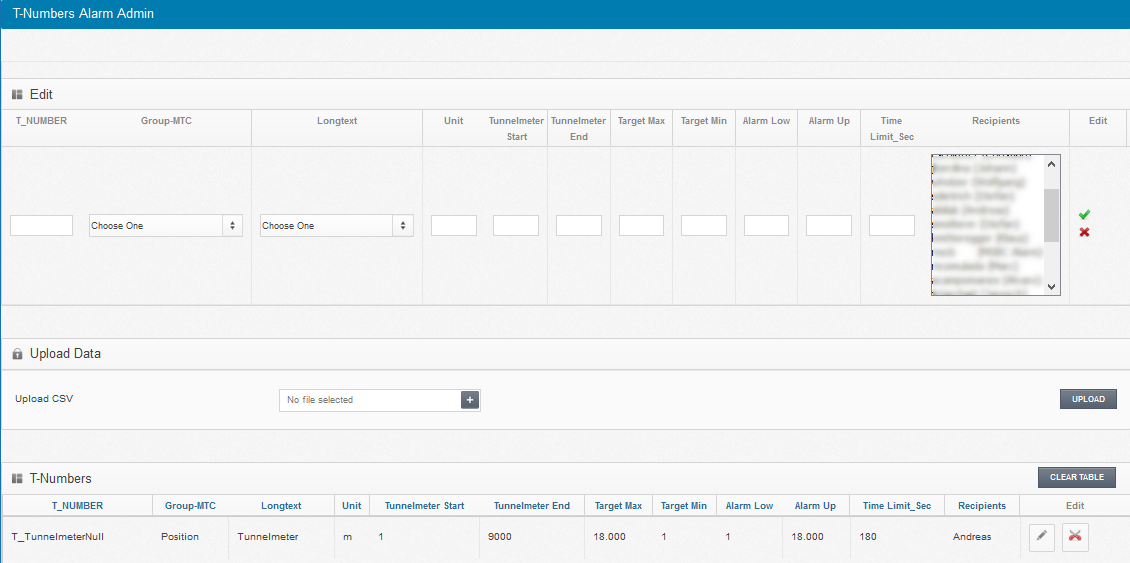

Limit and alarm values are also stored in the system and can be

configured for an automatic alarm messaging in case of breaking

their thresholds.

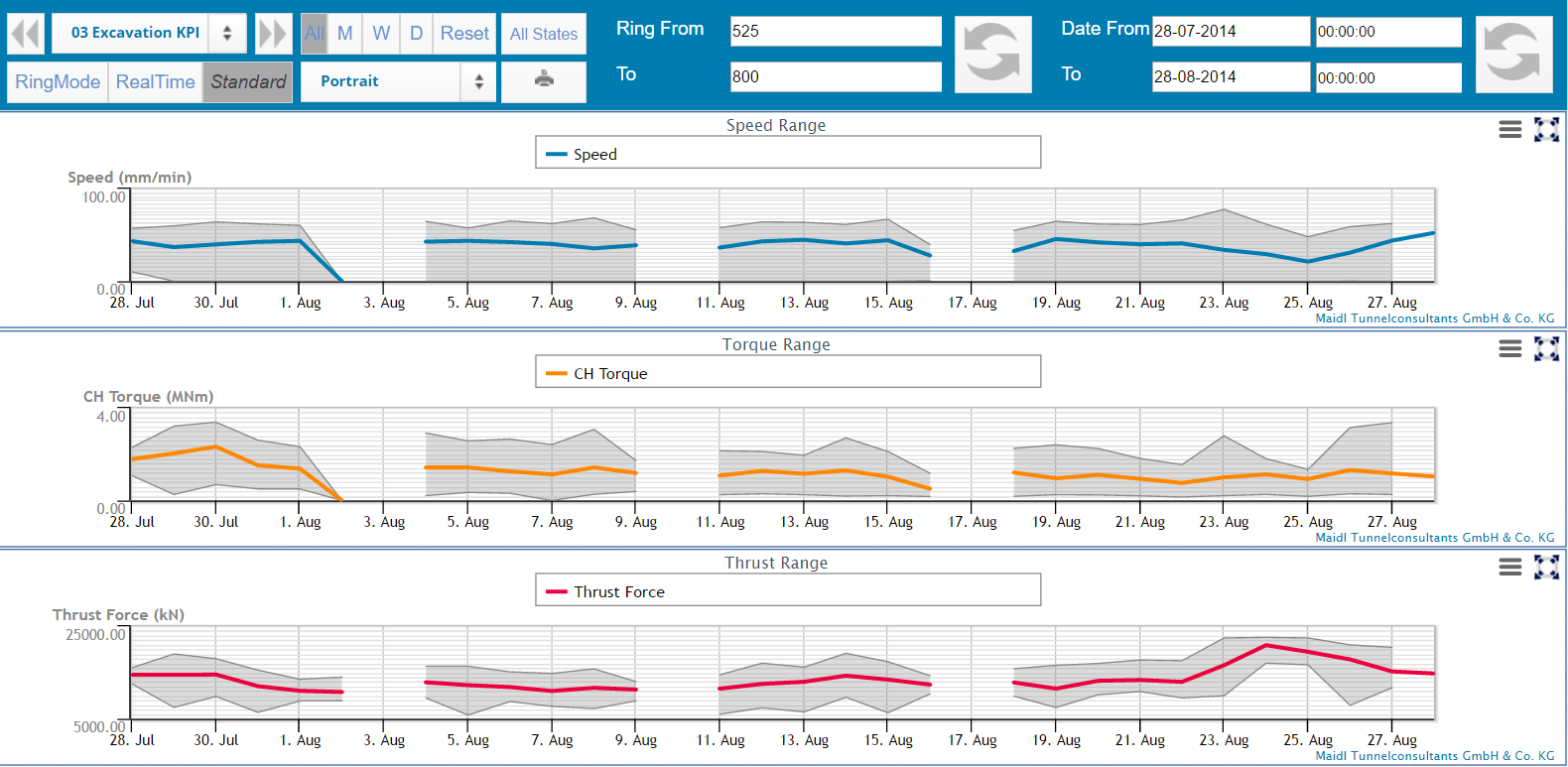

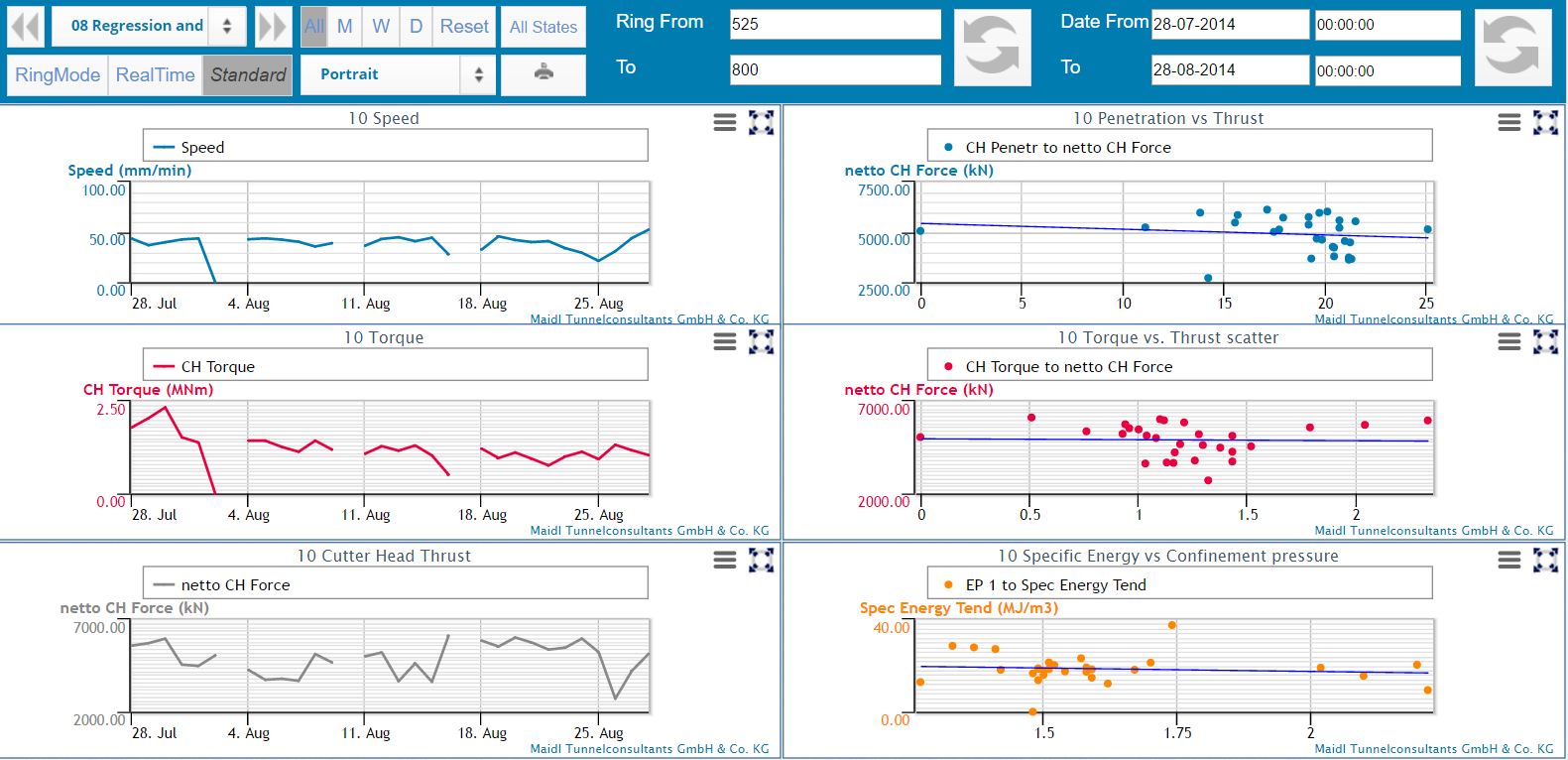

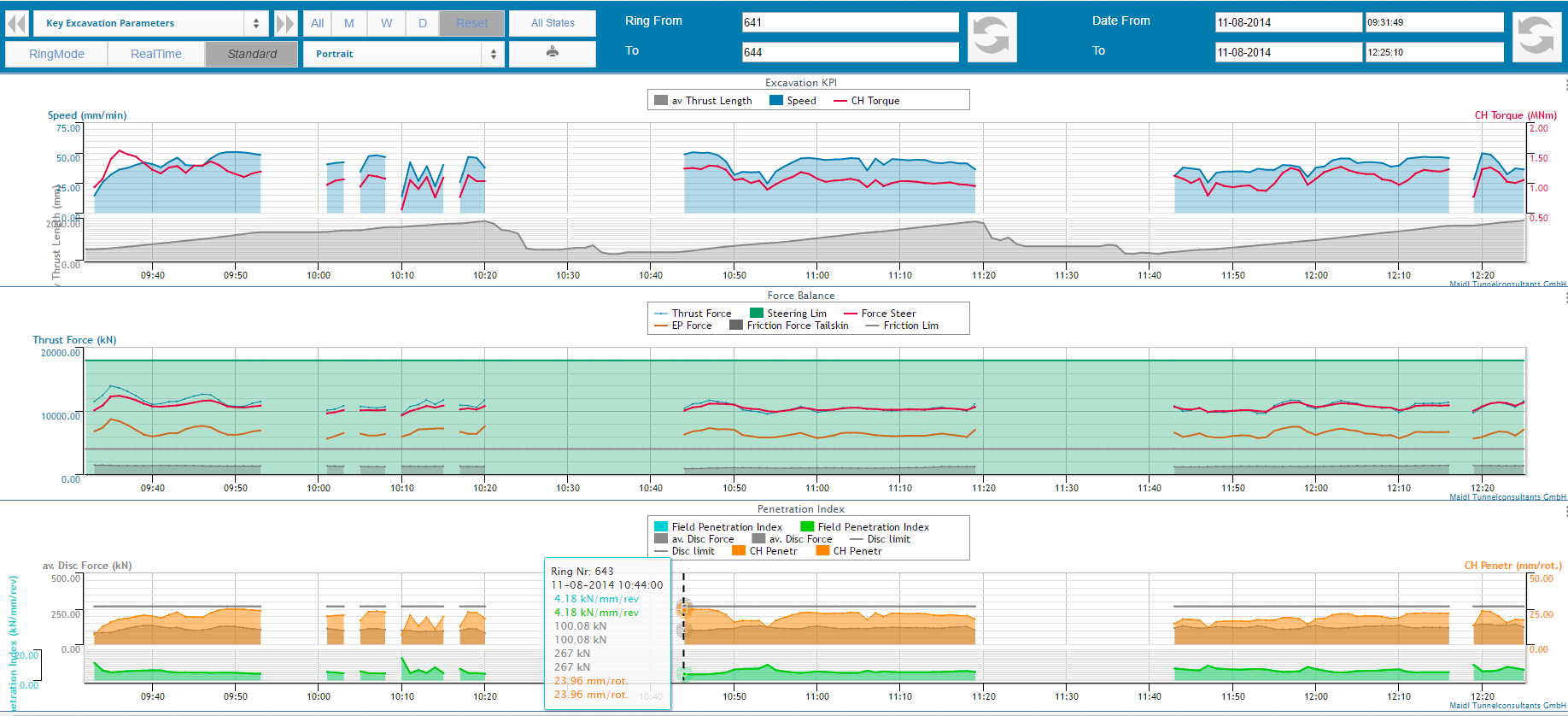

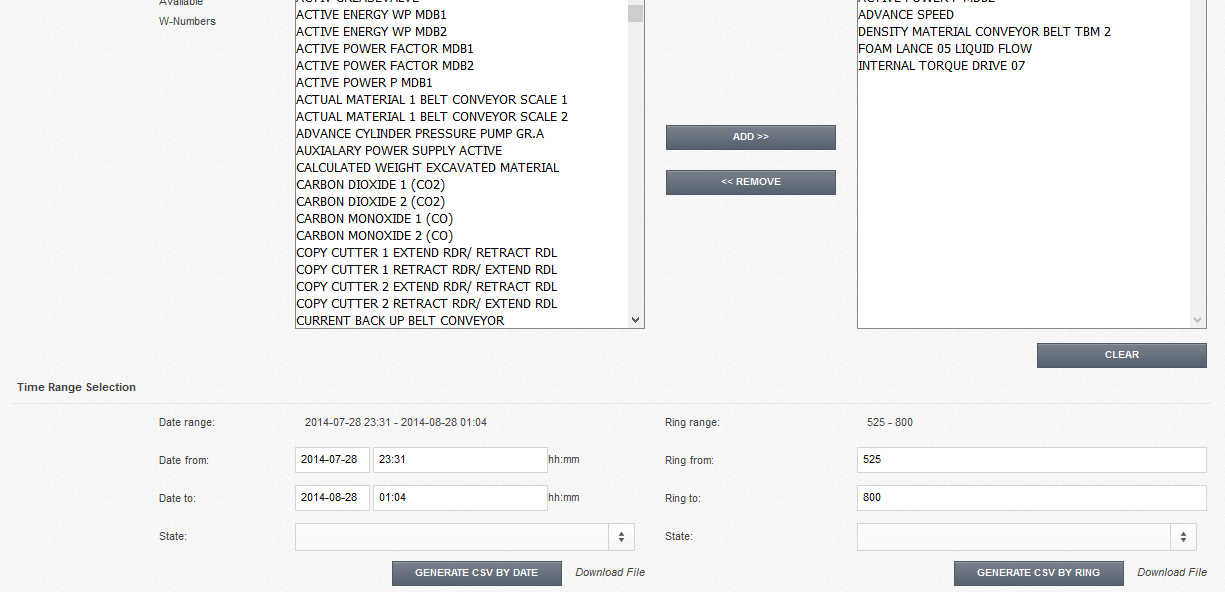

In addition to sensor values, also

calculated and aggregated values (minima, maxima, averages,

cumulated values, etc.) can be defined used for further analyses

and visualizations. Thus, for example, interactions between

different parameters can be identified and investigated.

Furthermore, it is possible to adapt the database to changes in

the data acquisition that occurs in a later stage of the project

using these customized calculation values without corrupting the

original data.

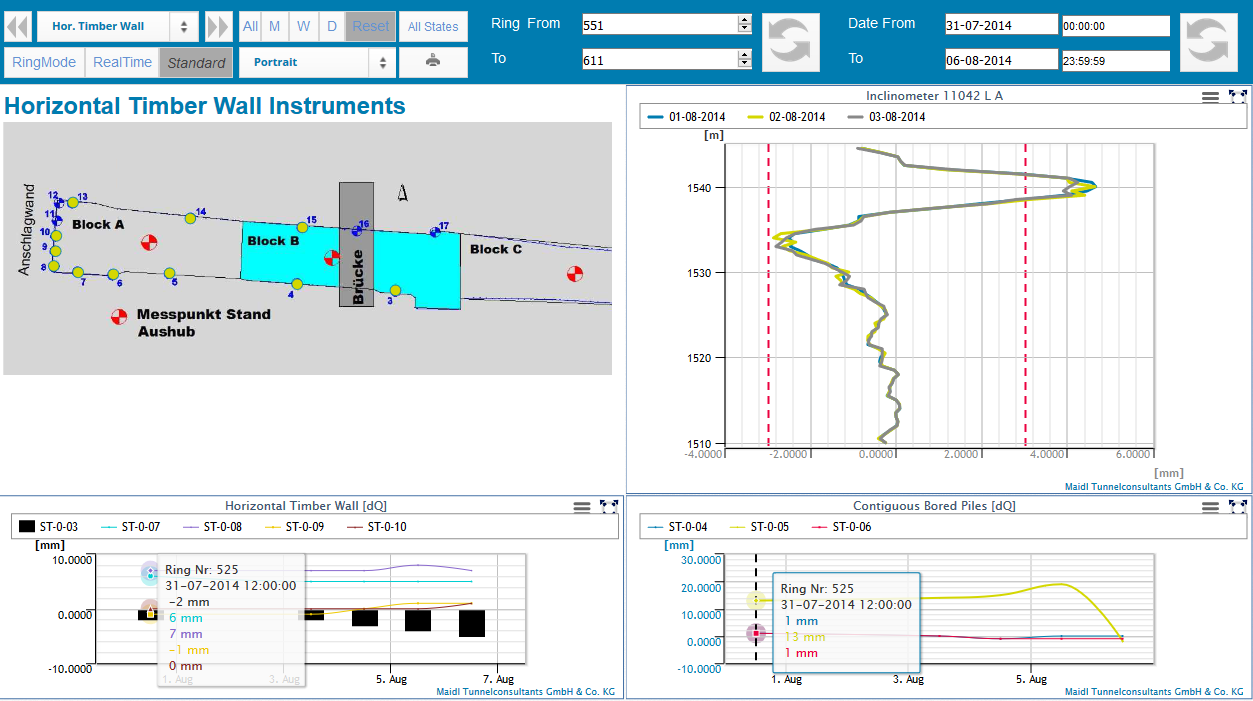

In addition to the various fields of

application of TBM data, PROCON can also integrate data from

various other data sources related to the tunneling project.

This can include data from the geo monitoring, the separation

plant or the ventilation system. All of this external data can

be assembled on PROCON dashboards along with critical TBM data

to get a holistic overview of the tunneling project.

The secured data hosting in a cloud

service computing centre ensures sustainable and secure

archiving of both automatically acquired and manually entered

data. The installation of special hardware on site is not

required. For full usability it is sufficient to set up a

reliable internet connection for the transfer of machine and

monitoring data from site to the PROCON II host.

In the following we invite you to an interactive

introduction tour to PROCON. In this process, the individual

features of PROCON are generally described and assigned to a link

to the software where you directly can test the introduced

features on your own.

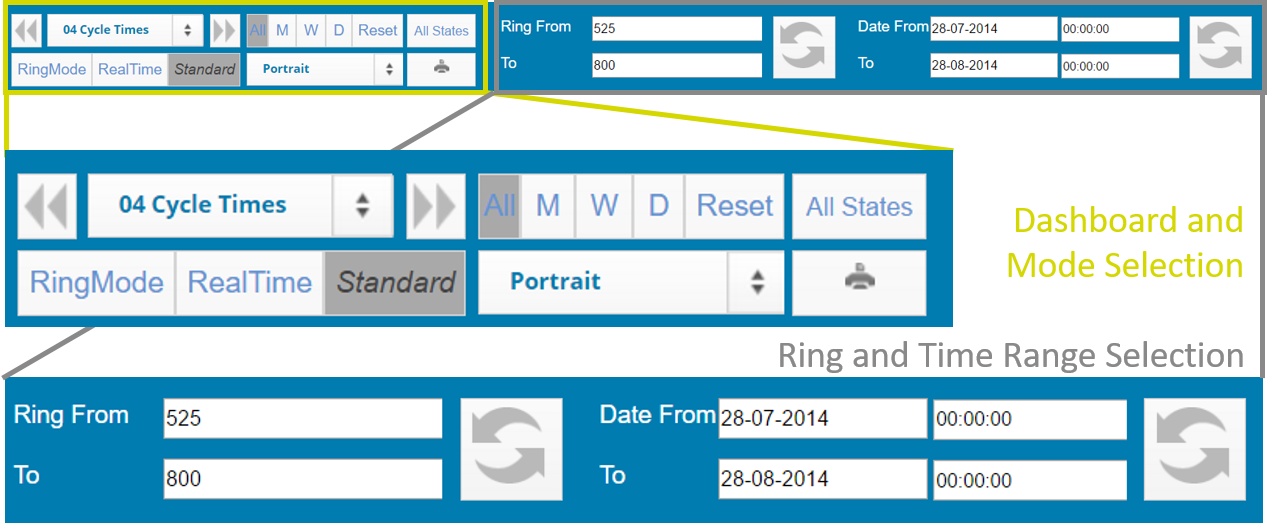

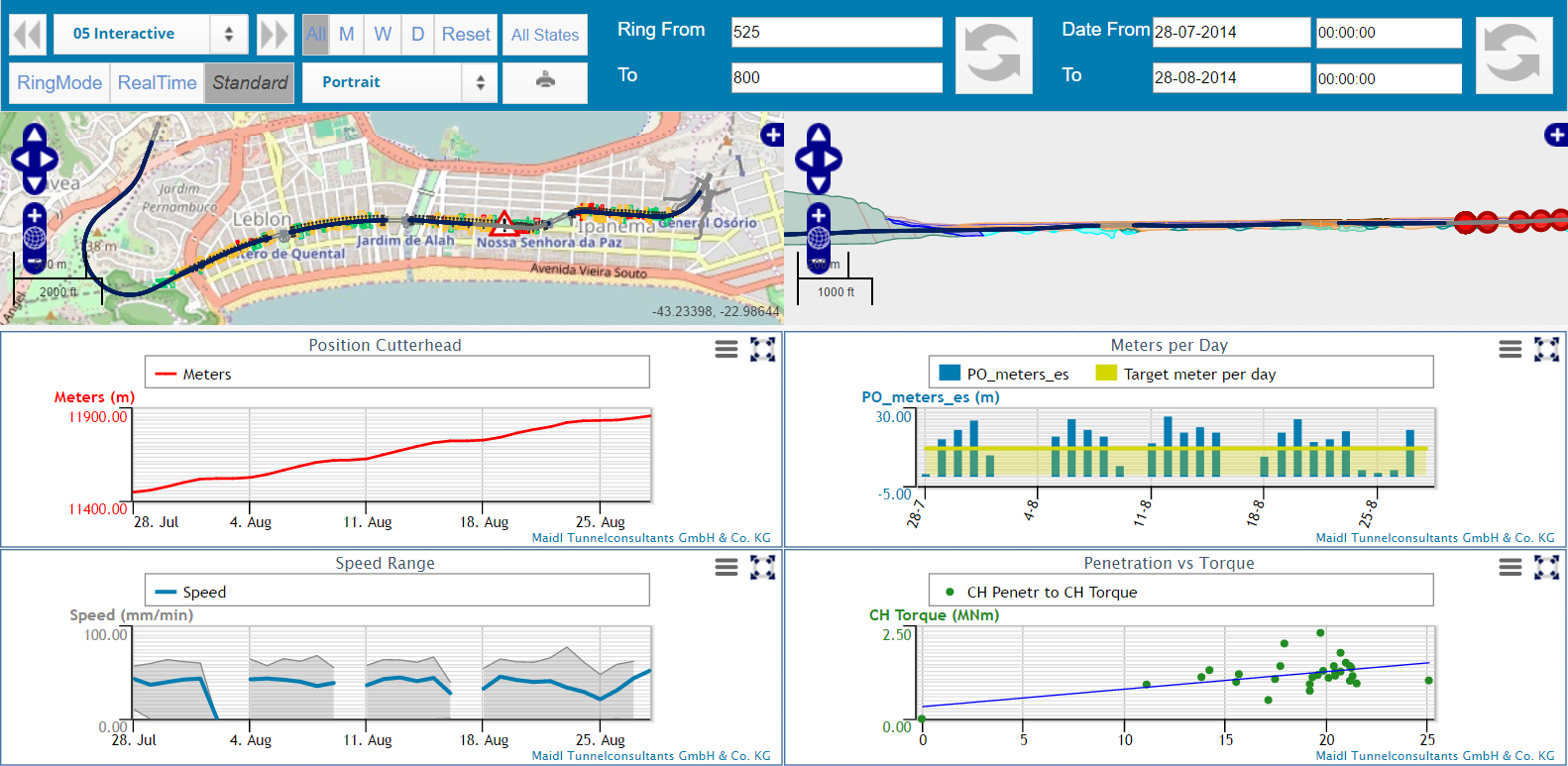

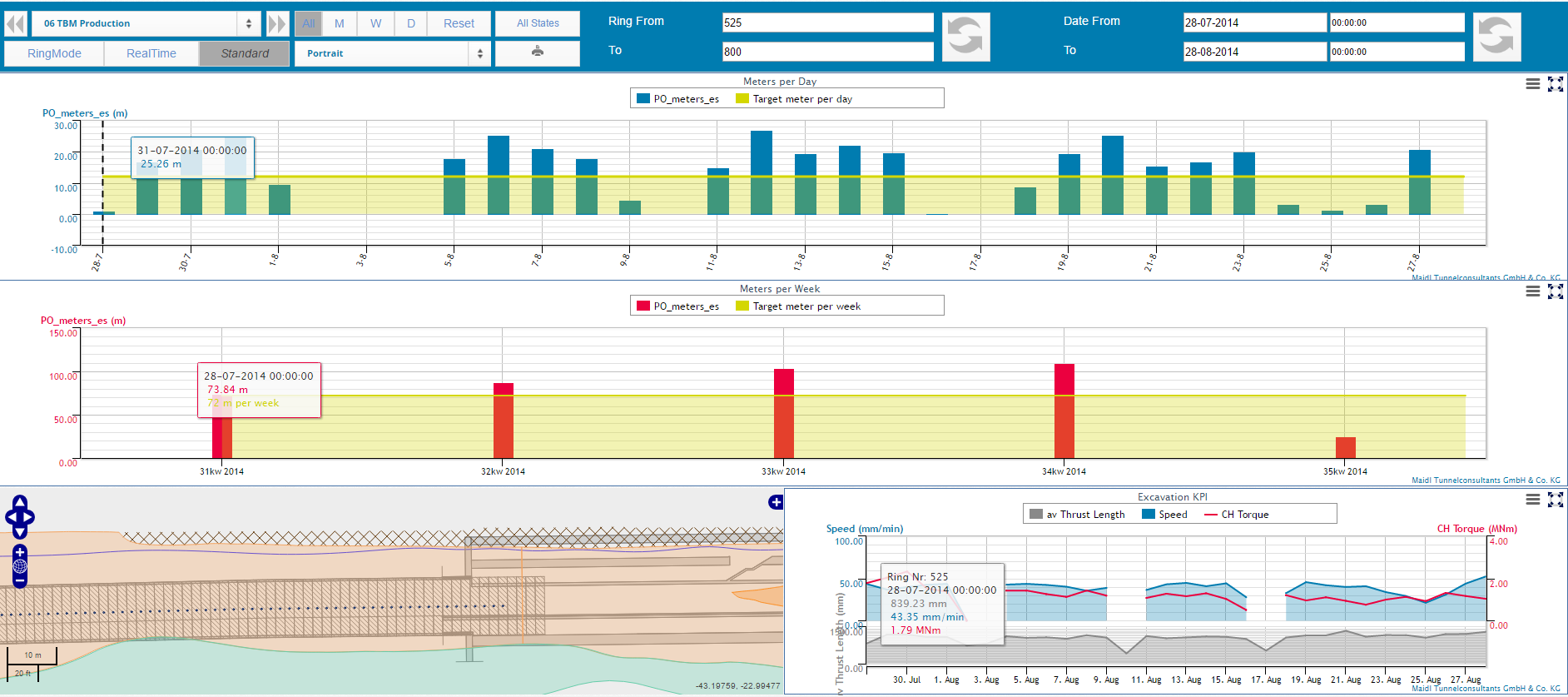

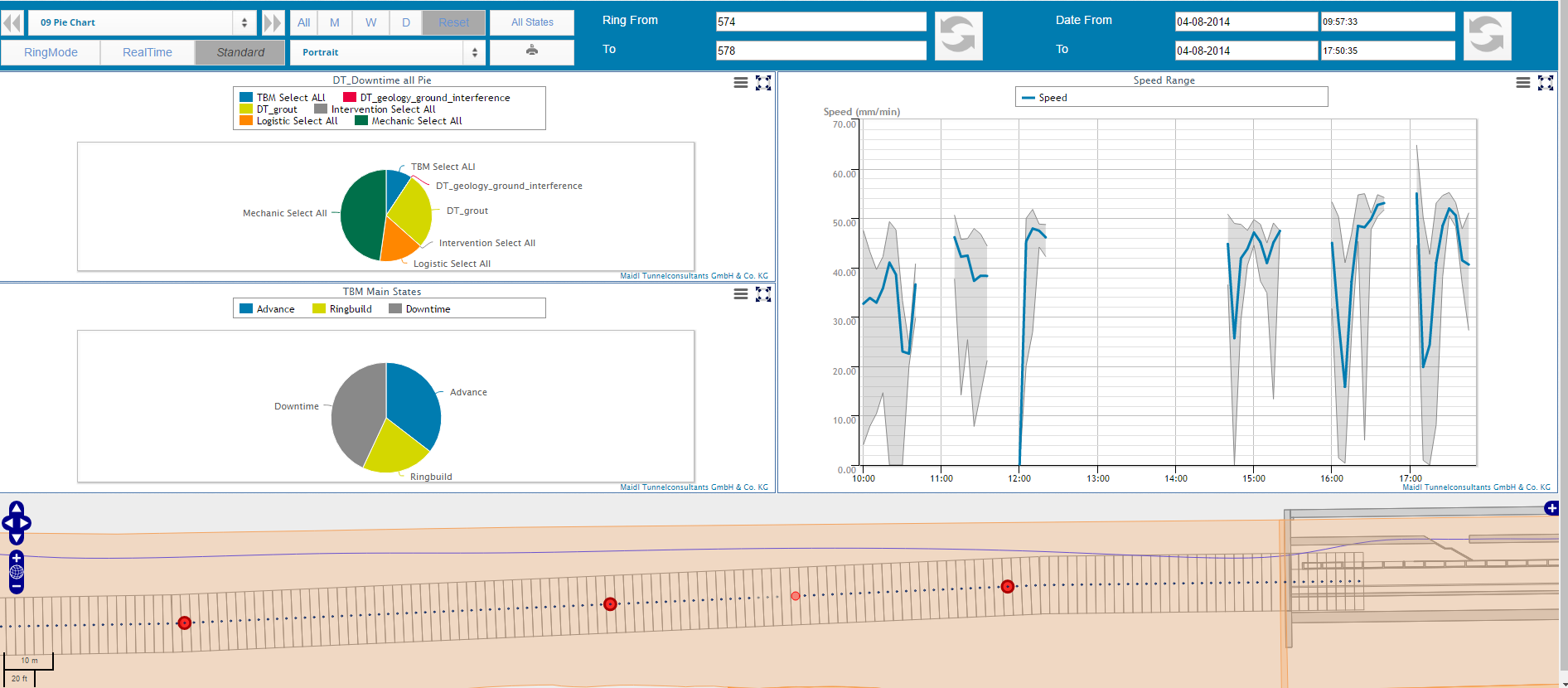

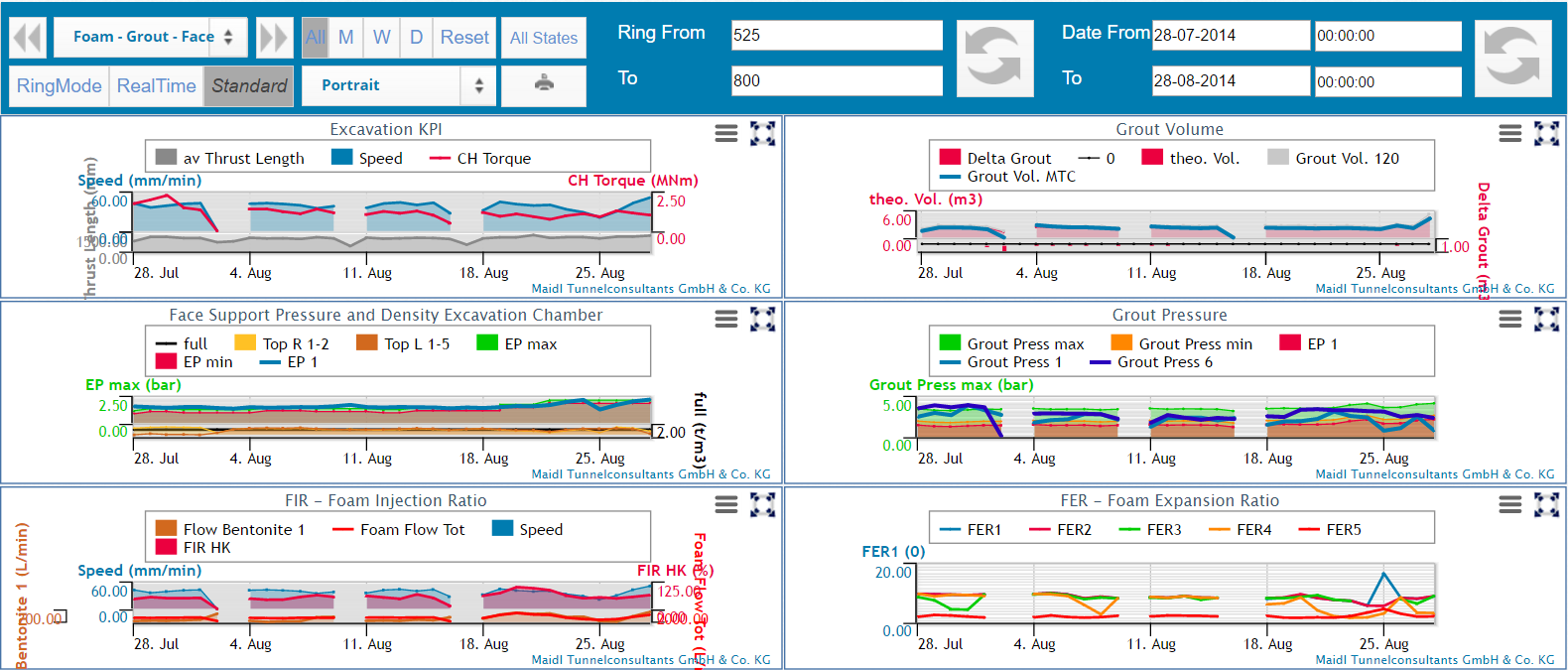

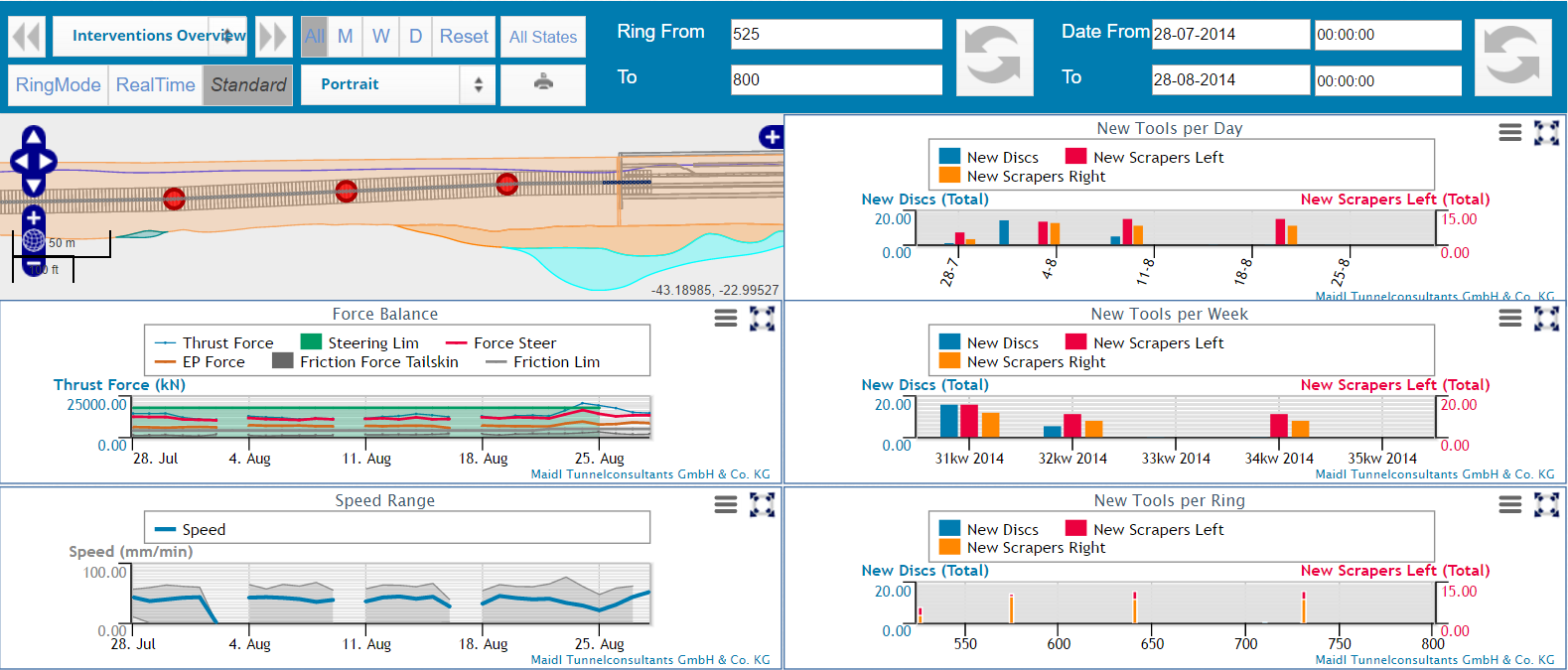

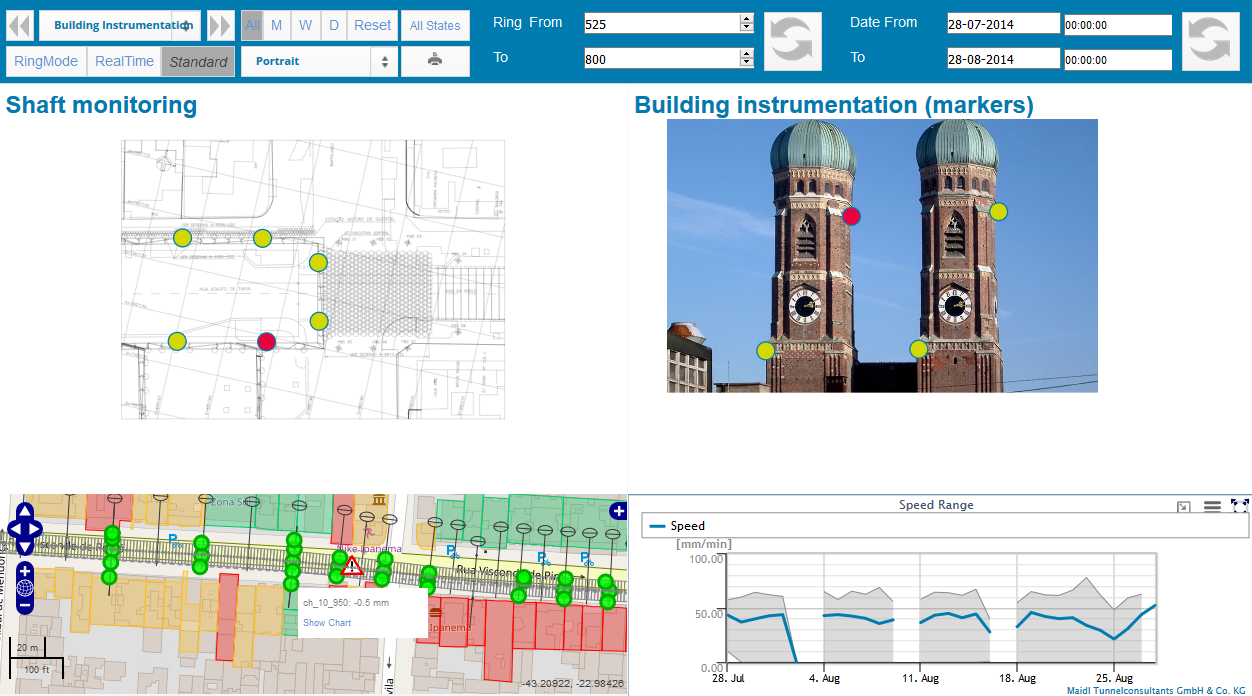

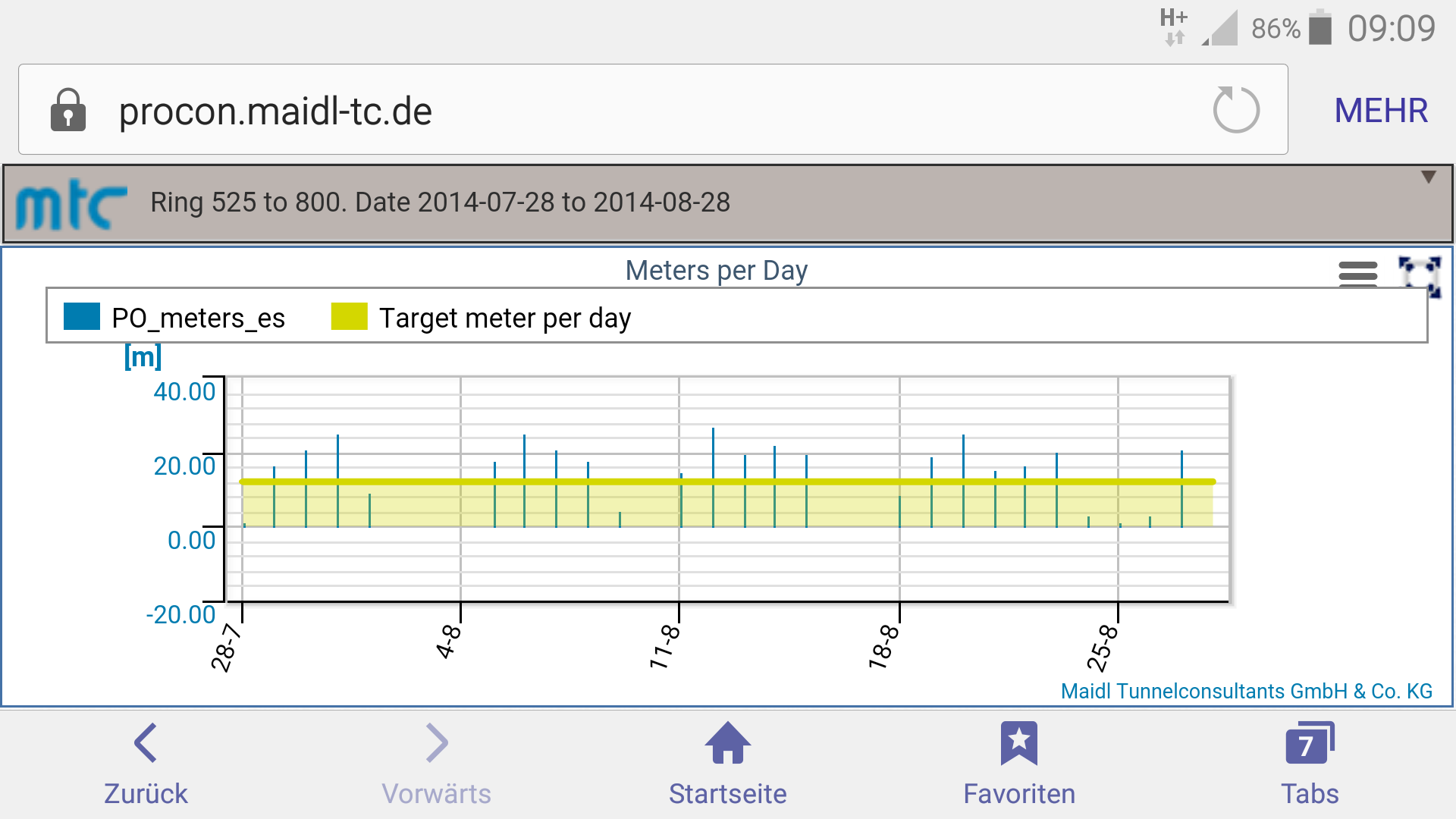

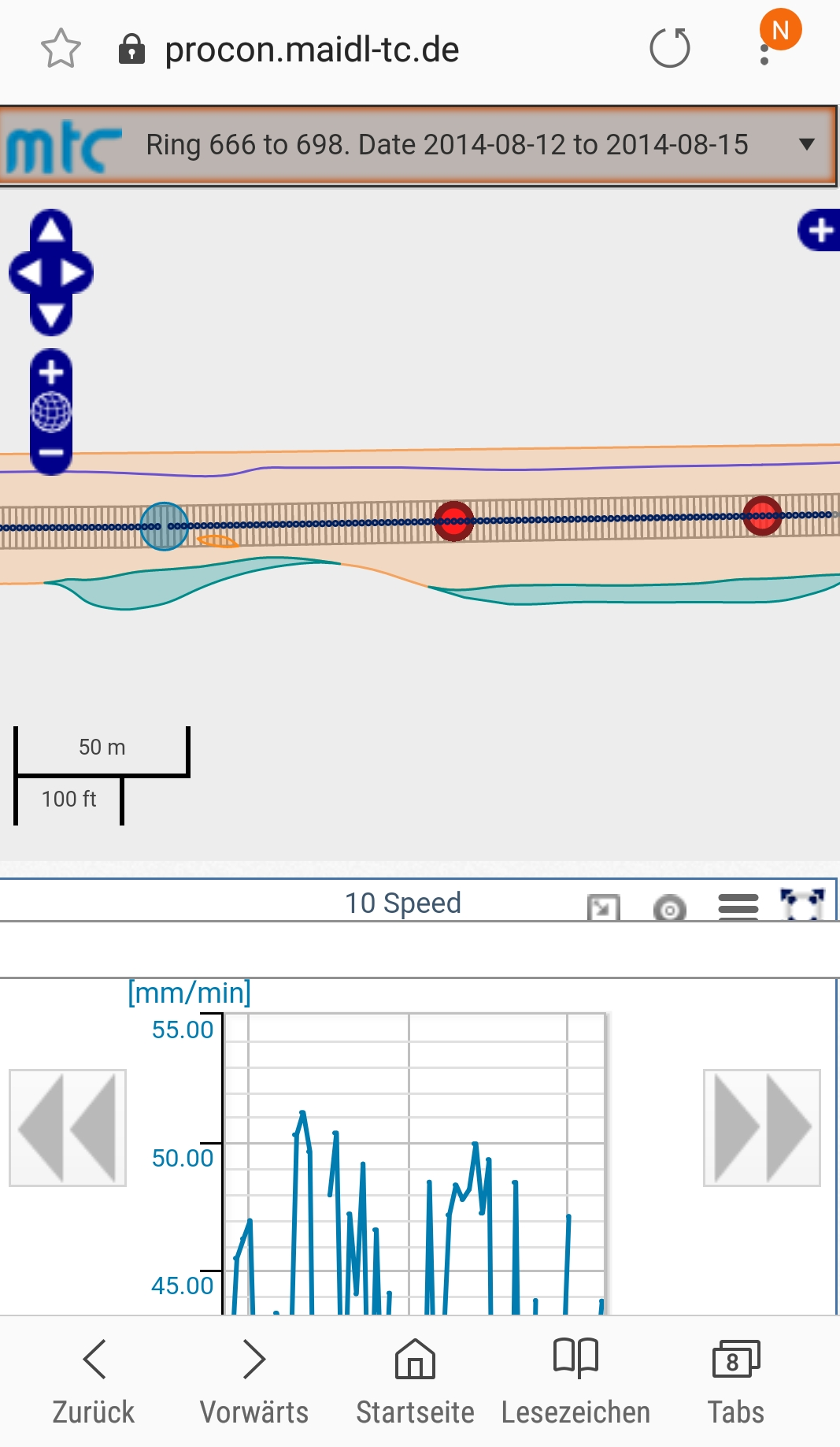

Dashboards

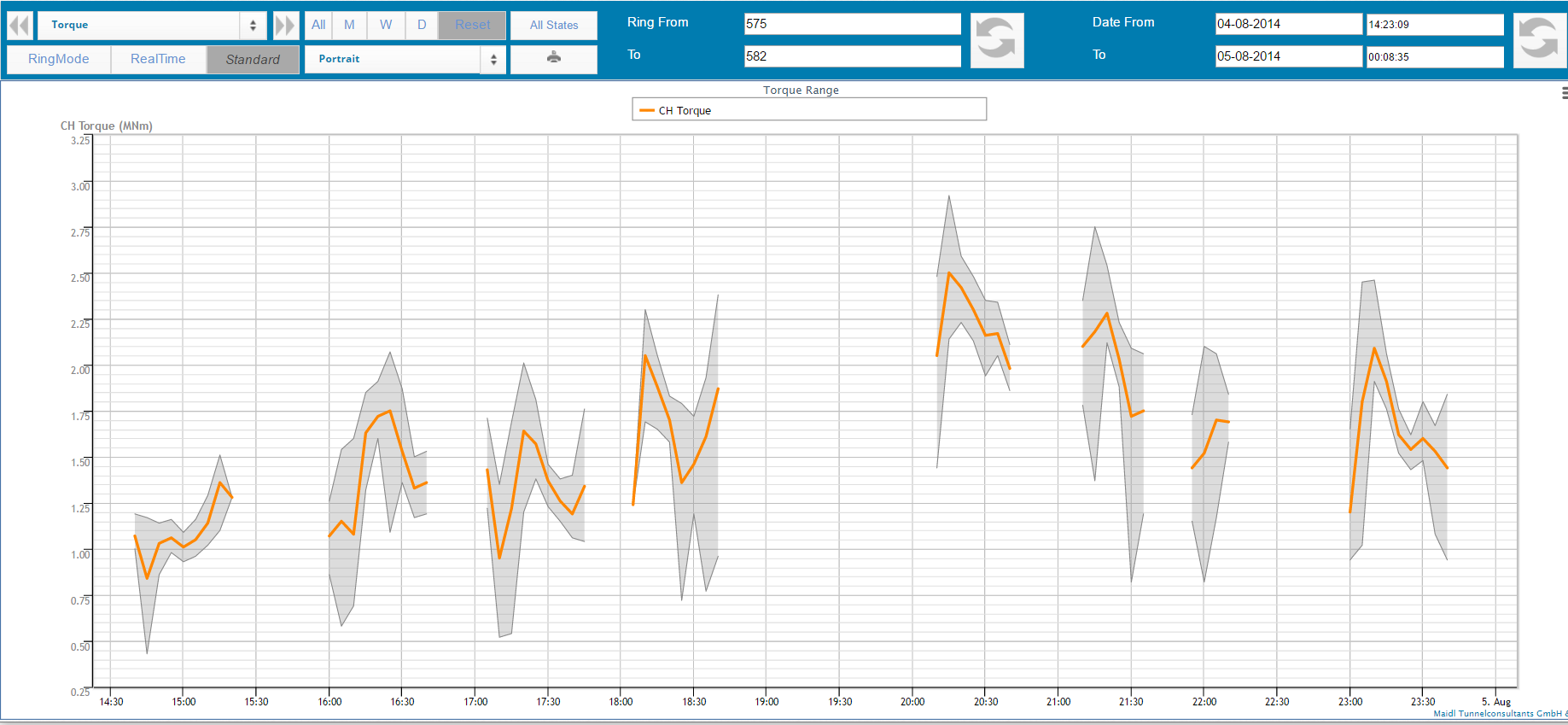

All data from the PROCON II data warehouse can be visualized by

means of interactive and customizable charts. These charts can be

directly zoomed, adjusted and arranged on specially developed

dashboards in the browser. These dashboards gather information of

specific topics and are used to display several sources of data

in a common reference system for immediate comparability. In this

context, your data is linked on dashboards with maps of a

geographic information system as well as a digital ground models

in a location or time reference system.

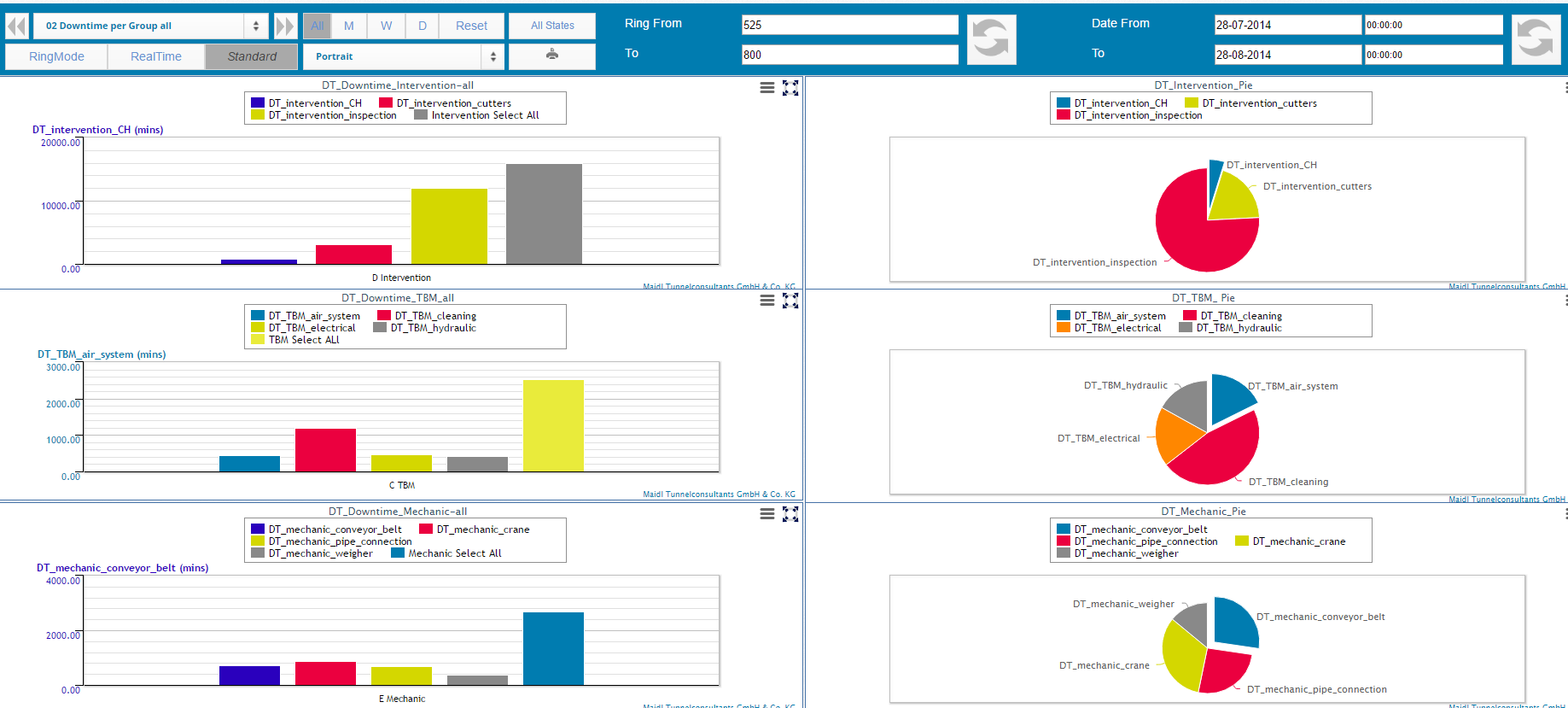

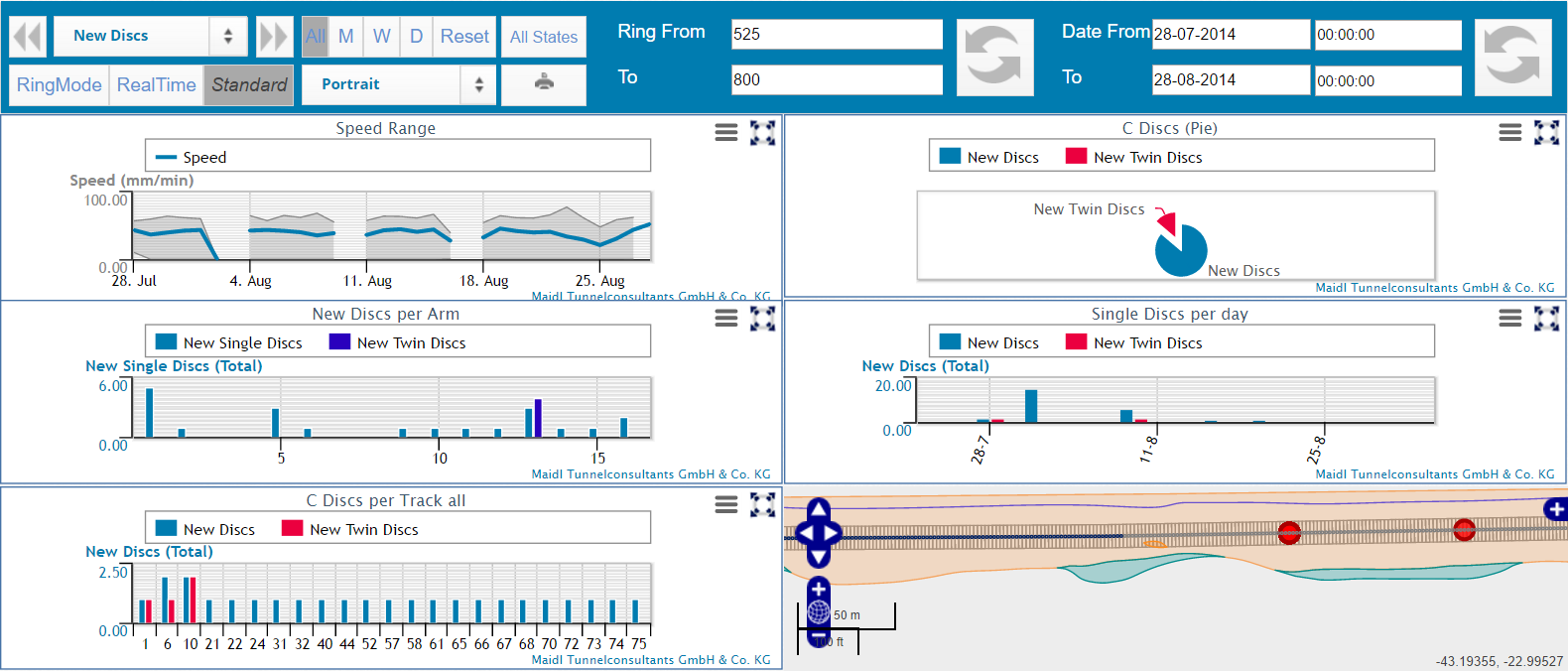

Each chart is

capable of displaying an arbitrary selection of machine data,

target values, additional information and calculated values in a

customizable visual appearance. For this purpose, line charts,

column charts and area charts are available. For suitable data

sources, also pie charts can be employed.

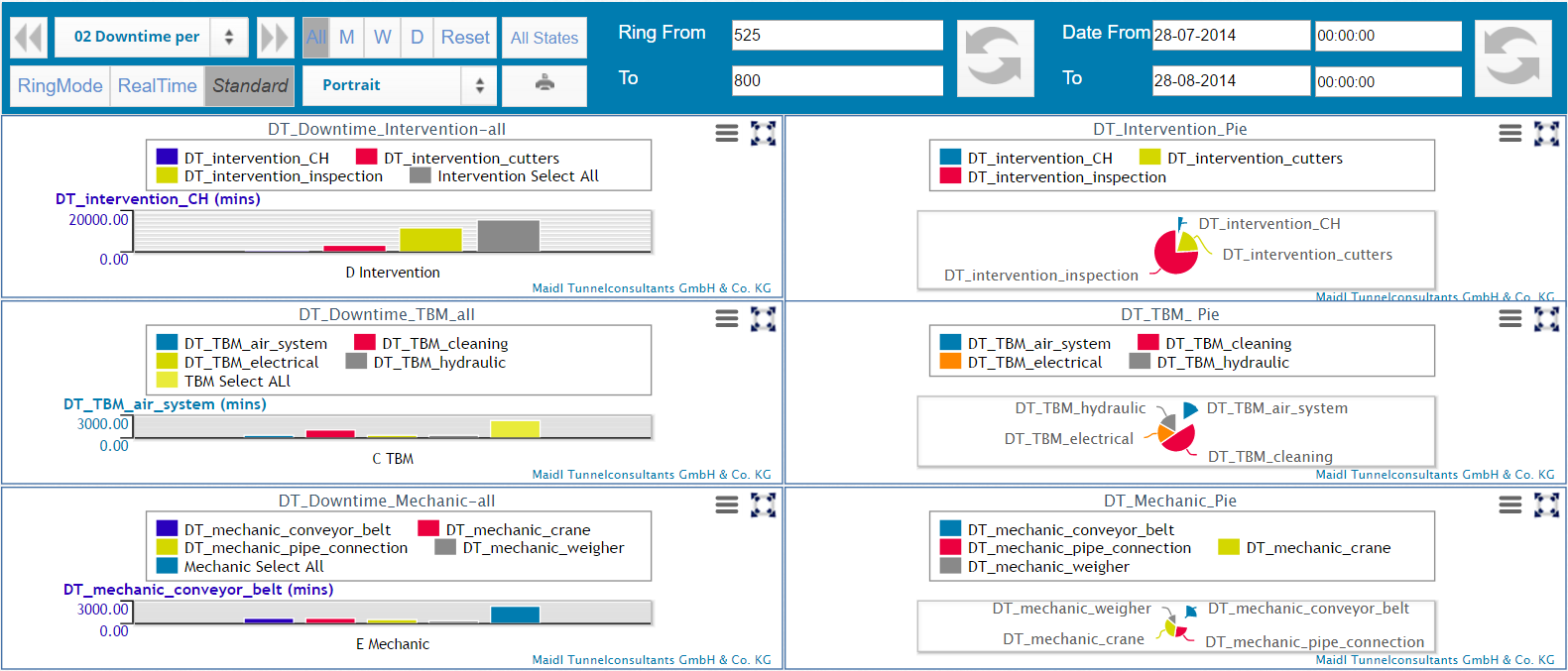

Advanced Analysis

The advanced analysis is a category for more sophisticated dashboards that are accessible for selected users of the system. It is reserved for complex topics, or deeper analyses of certain processes.

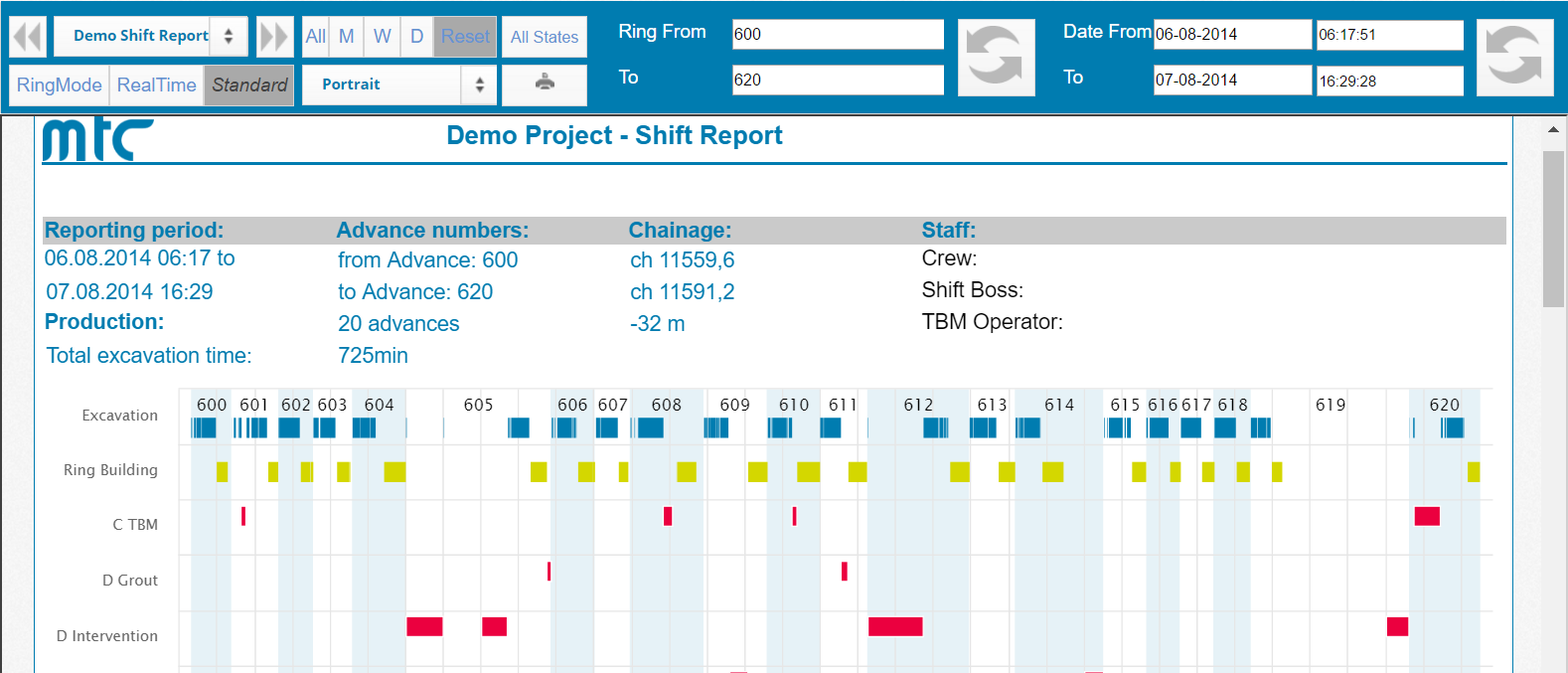

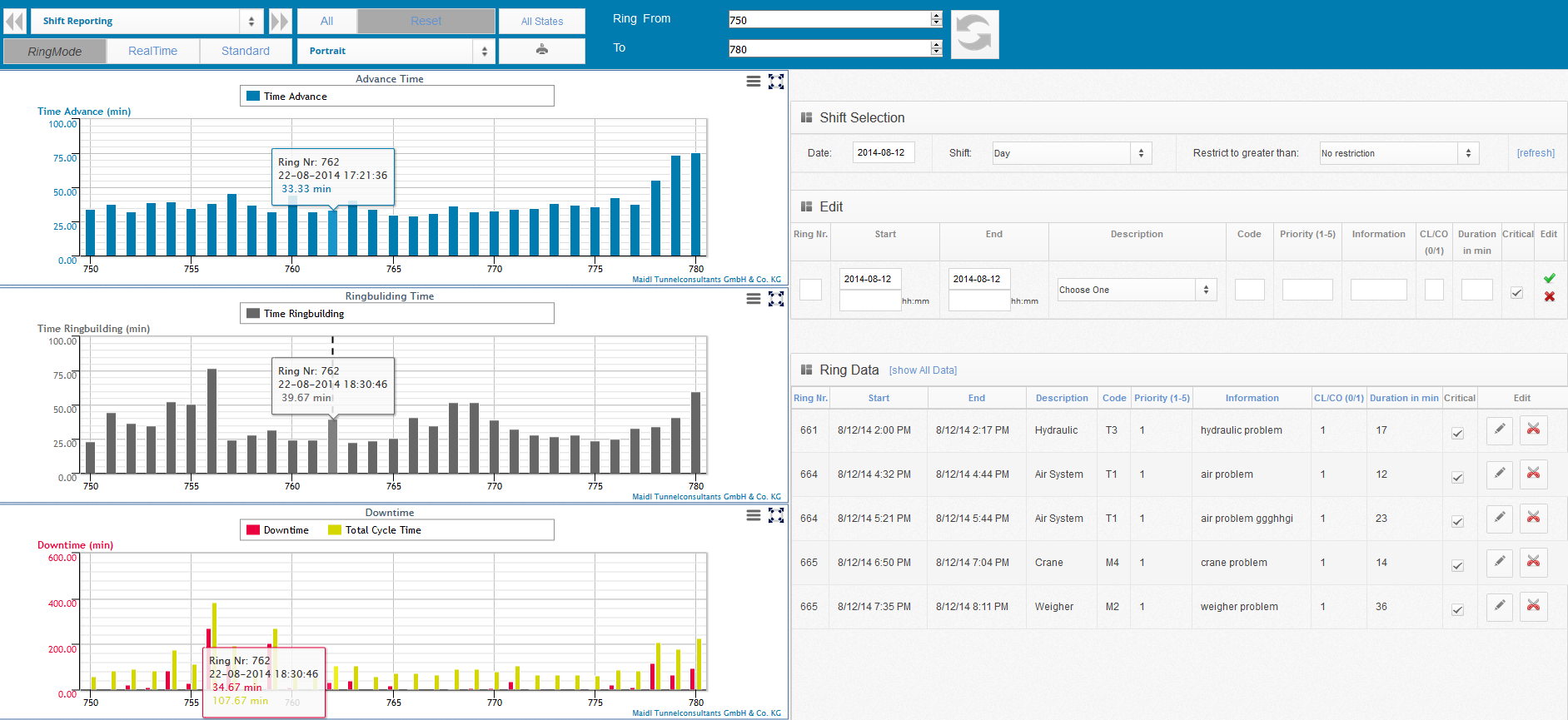

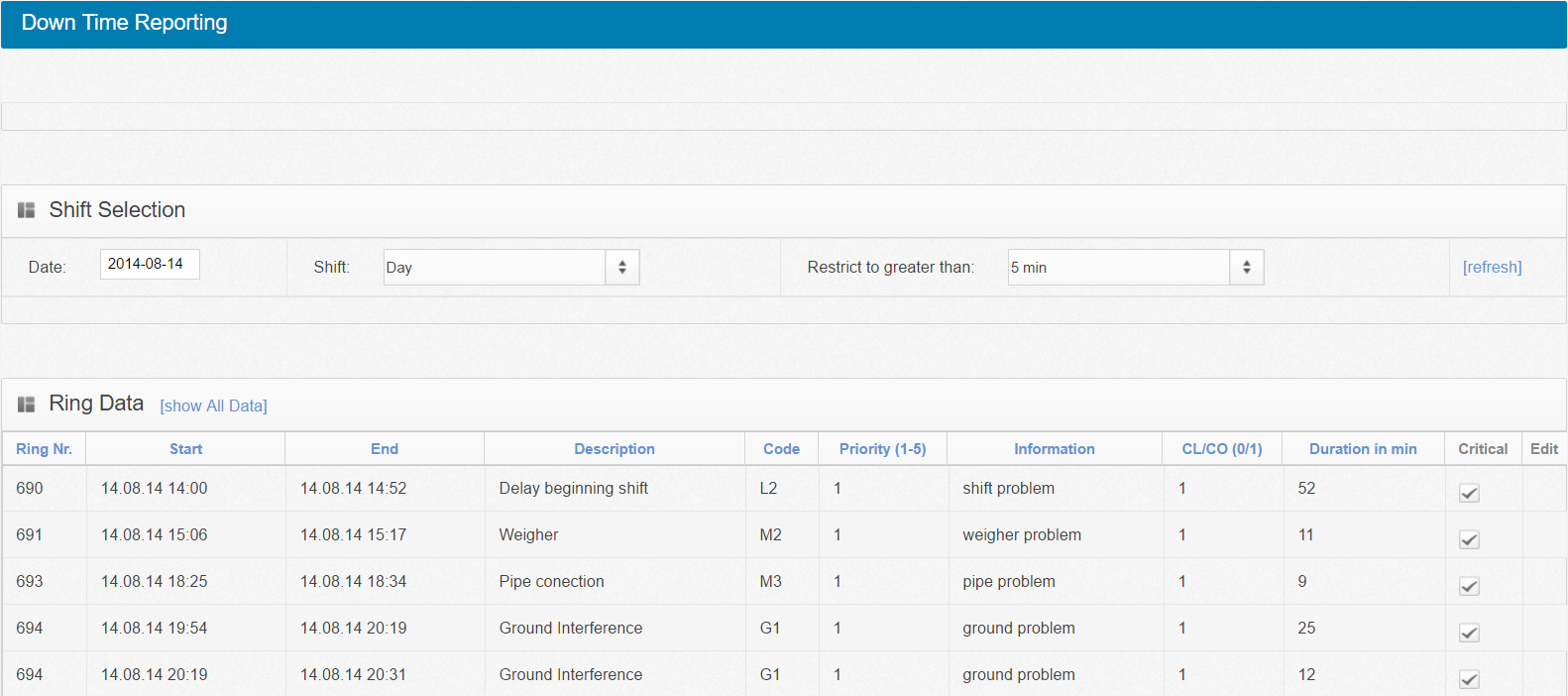

Shift Reporting

An interactive module for shift protocols extends the list of

optional features of PROCON. Extracting periods of advance, ring

building and standstill automatically from the machine data,

these time intervals are displayed using a Gantt chart

visualization for each shift.

Shift reporting represents

an essential element of the documentation of a tunneling project.

All actions are documented and can be evaluated as well as

exported. In Procon II, multiple types of shifts per day can be

generated like a morning, day and late shift. The key processes

like advance and ring build are automatically retrieved from the

machine data and assigned to each shift. The reason for each

downtime slot needs to be specified by the user. Here, the

catalog of downtimes is specified according to each project's

requirements. Based on the documented downtime reasons,

evaluations can be performed based on which the process can be

optimized.

For detail evaluations, additional filters on

specific shifts or staff members can be used, hence allowing for

an assessment of reasons for performance differences among the

shifts or to identify specific parameters that correlate with the

performance. The integrative nature of the data warehouse and the

unified temporal and spatial reference system helps identifying

previously unknown interactions and hidden mechanisms in the

process.

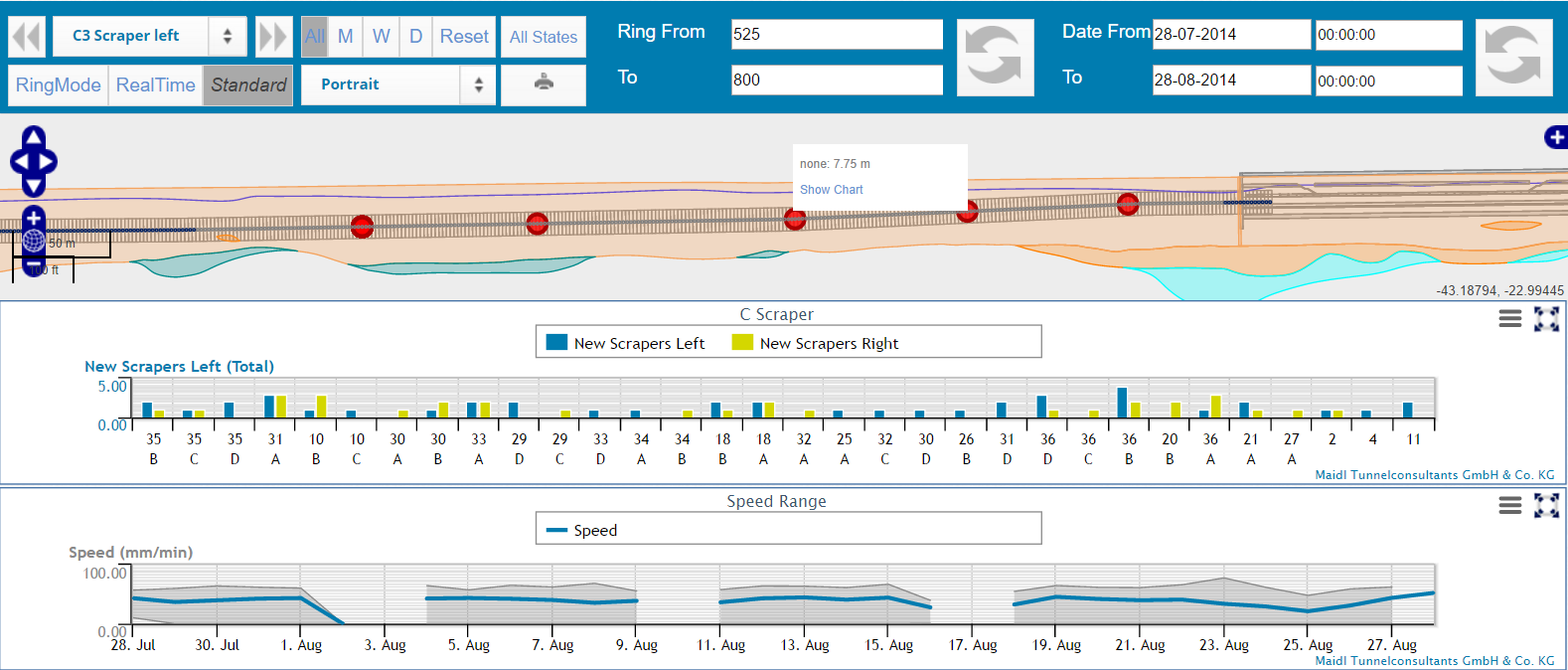

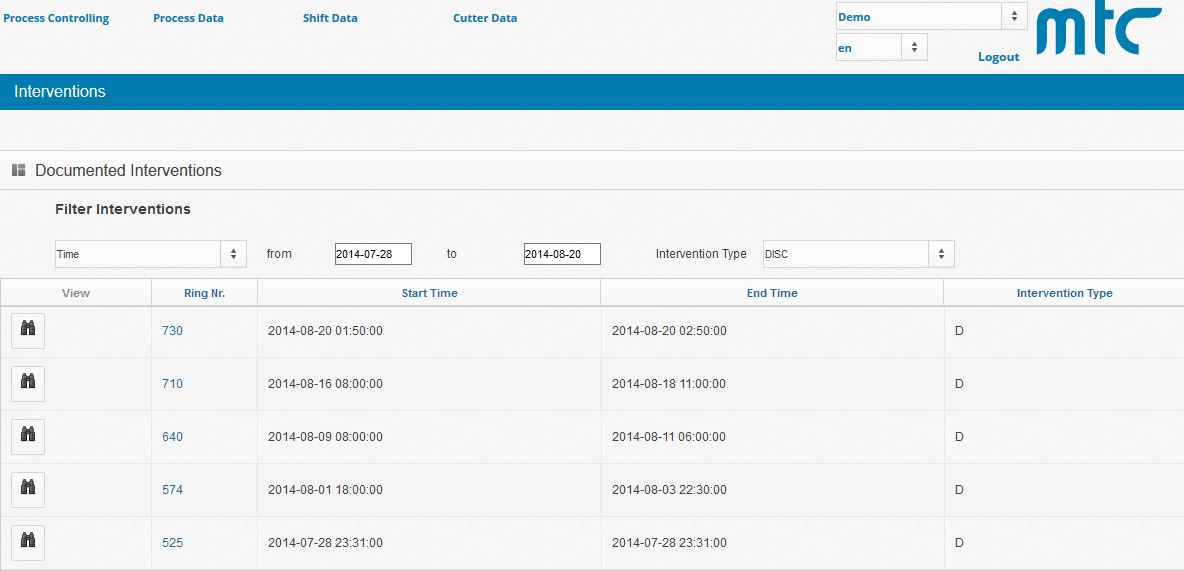

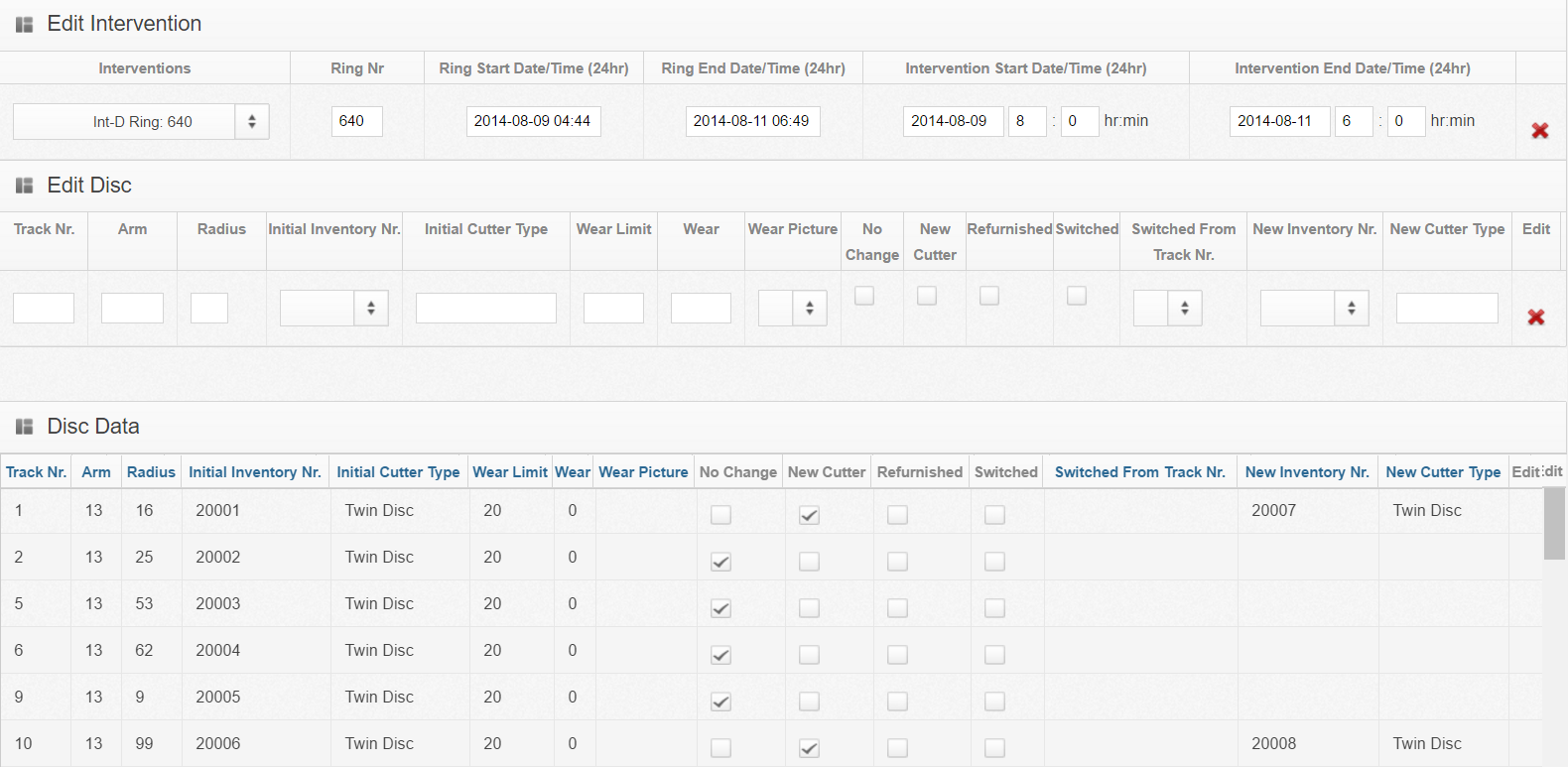

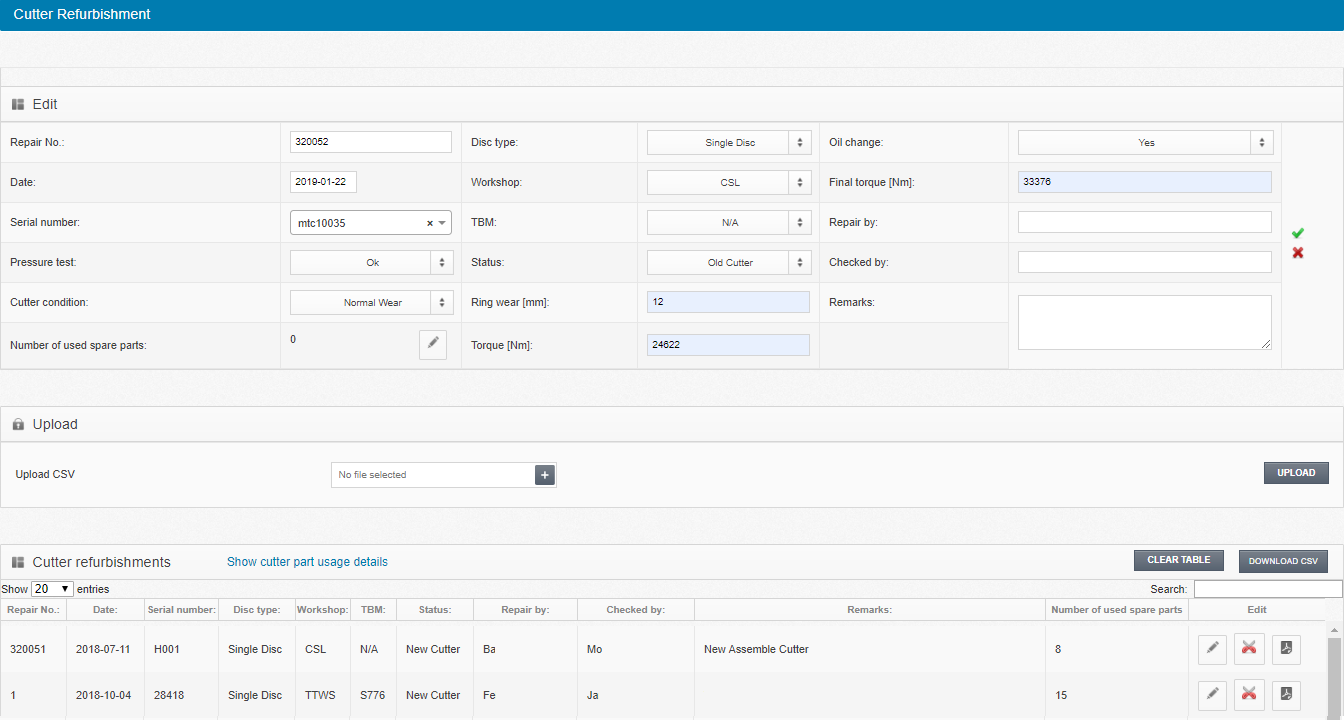

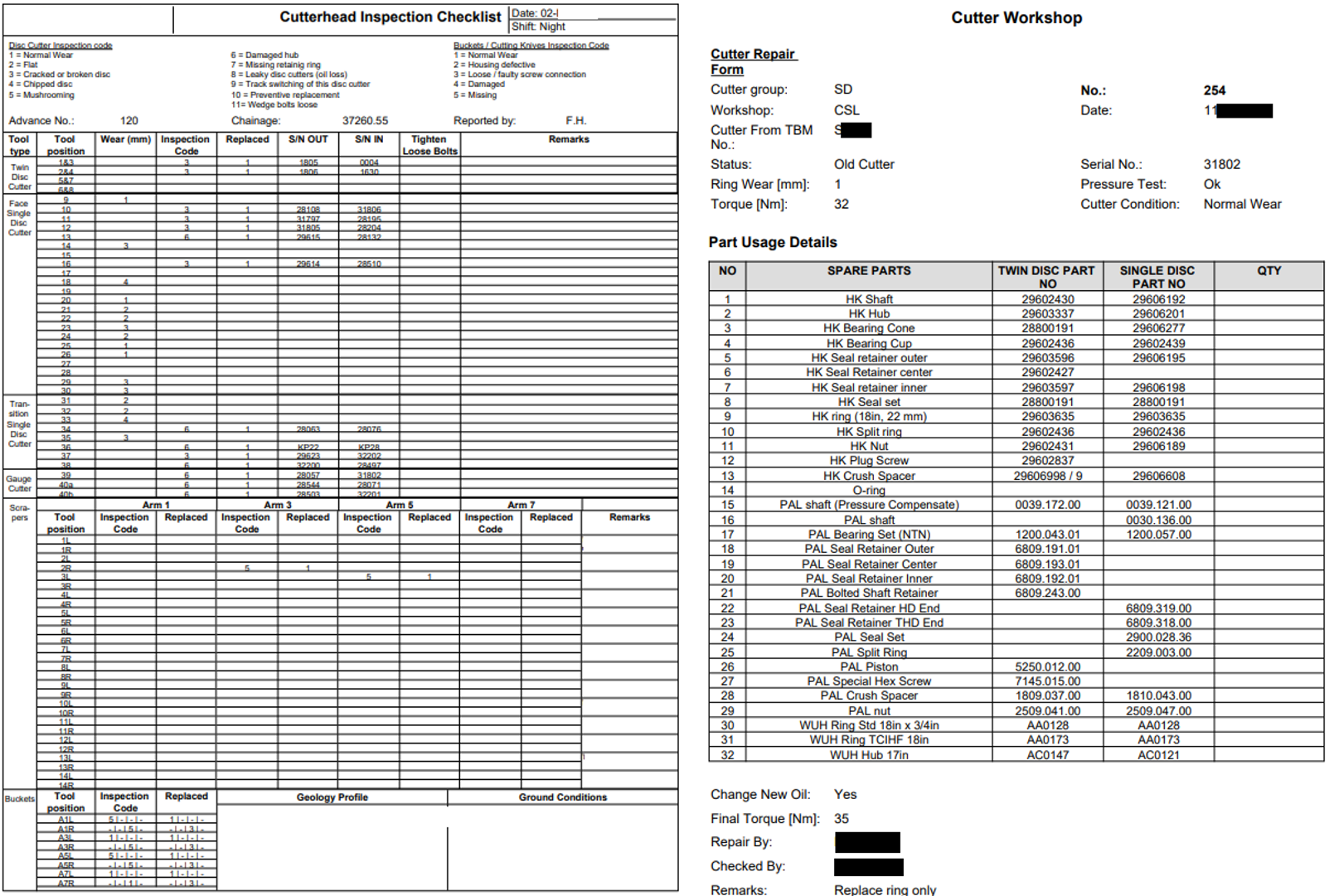

Cutter Tool Management

The management of cutter tools is very important especially when

excavating in hard rock. The wear of the individual cutter tools

must be documented to prevent the tunneling machine from being

damaged due to worn-out tools. In Procon II, the individual tools

can be registered and maintained. Data can be entered based on

interventions which represents an event when the cutter tools are

checked for their current wear and changed, if required. Types of

cutting tools like disks, scrapers and buckets are distinguished

in the system and can be managed in respective user interfaces.

The entered intervention data can be displayed using Procon's

chart and dashboard configurators. Here, the tool consumption can

be correlated with machine data and geology information. Thus,

evaluations can be performed of the required tools in context of

the excavated ground. Following the identification of those wear

mechanisms, the prediction of the tool service life can be

improved and maintenance intervals can be optimized, reducing the

risk of unplanned standstills.

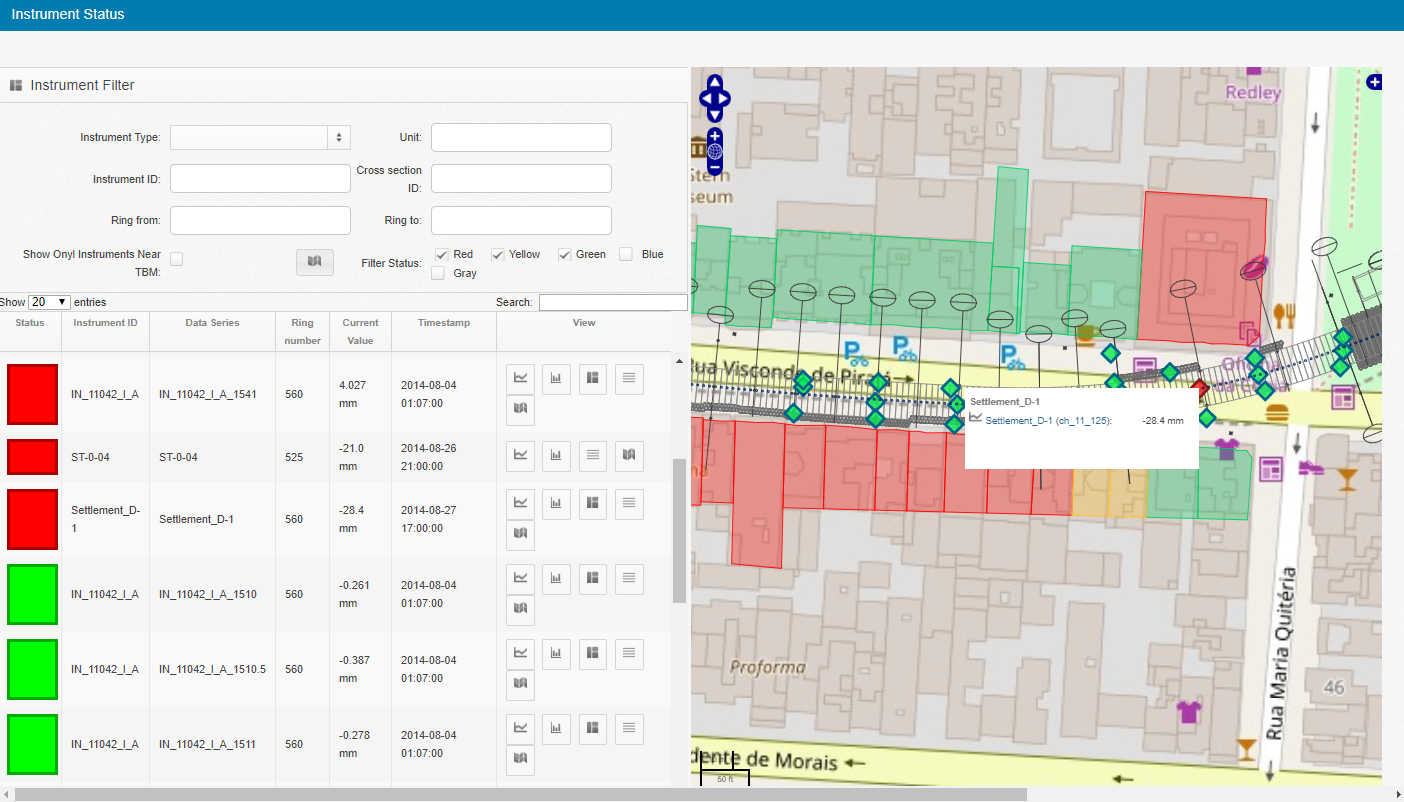

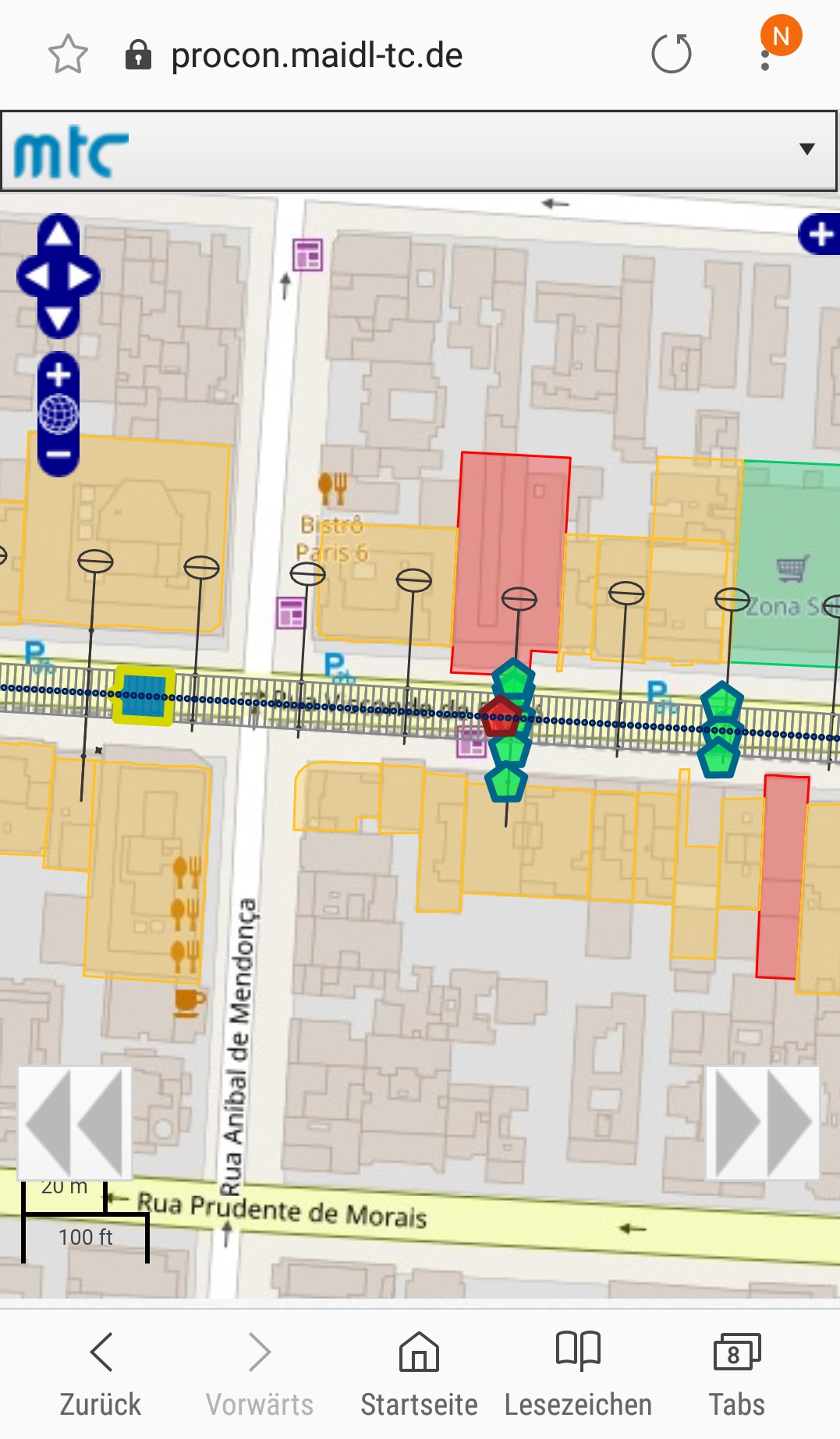

Monitoring

In an integrated additional database, monitoring data is stored

that is retrieved from arbitrary instruments registered in the

PROCON II data warehouse. Here, an instrument consists of a

number of data series which contain the individual data. For each

instrument the position and its assignment to a specific class of

instrument (e.g. extensometers or leveling points) is captured.

The data series contain additional information regarding their

assignment to a monitoring section and their warning and alarm

levels which can then be applied to determine the status of the

instrument. Using this information, the location and the time of

measurement of each data entry is connected with the project

reference system.

This allows specific visualization

options for monitoring data. The development of settlement

troughs, for example, can by shown by visualizing monitoring

cross-sections.

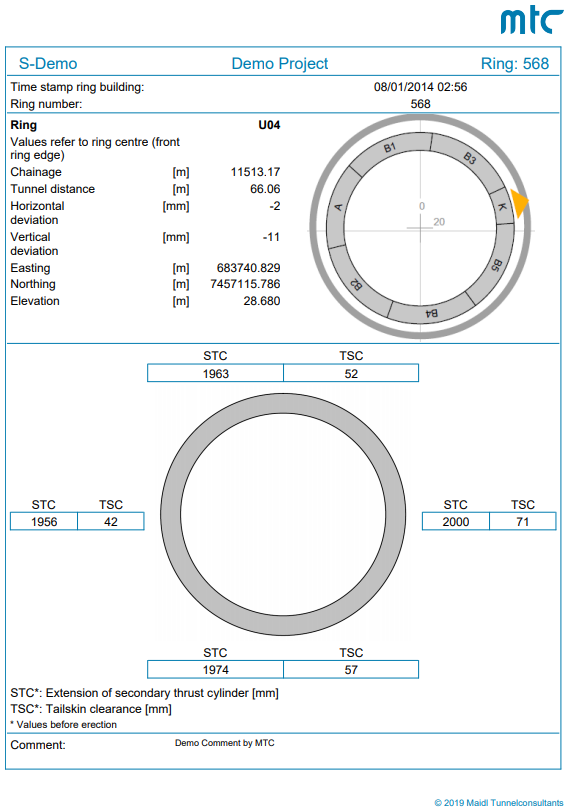

Reporting

The documentation of the tunneling process is essential due to

many aspects. Therefore, Procon II offers custom-designed machine

data reports, intervention reports and shift protocols as

printable reports to document the progress. Upon setup of the

project, MTC considers the project-specific requirements and

prepares automatically updating report templates via the web

interface. Reporting periods and various filter functions can be

arbitrarily selected.

The reports can be arranged in

dashboards to allow for adjustments of reporting periods and to

add manual annotations before downloadind and printing them.

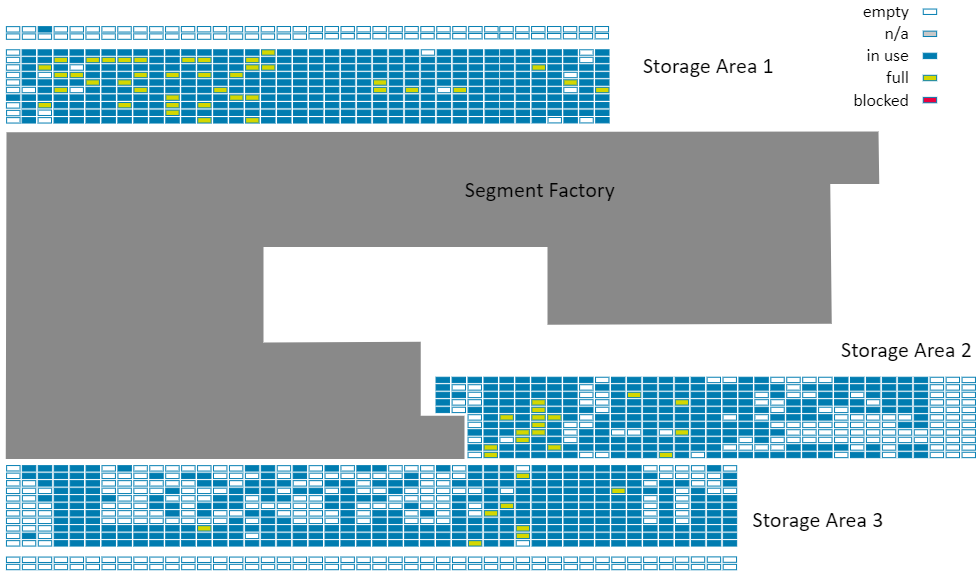

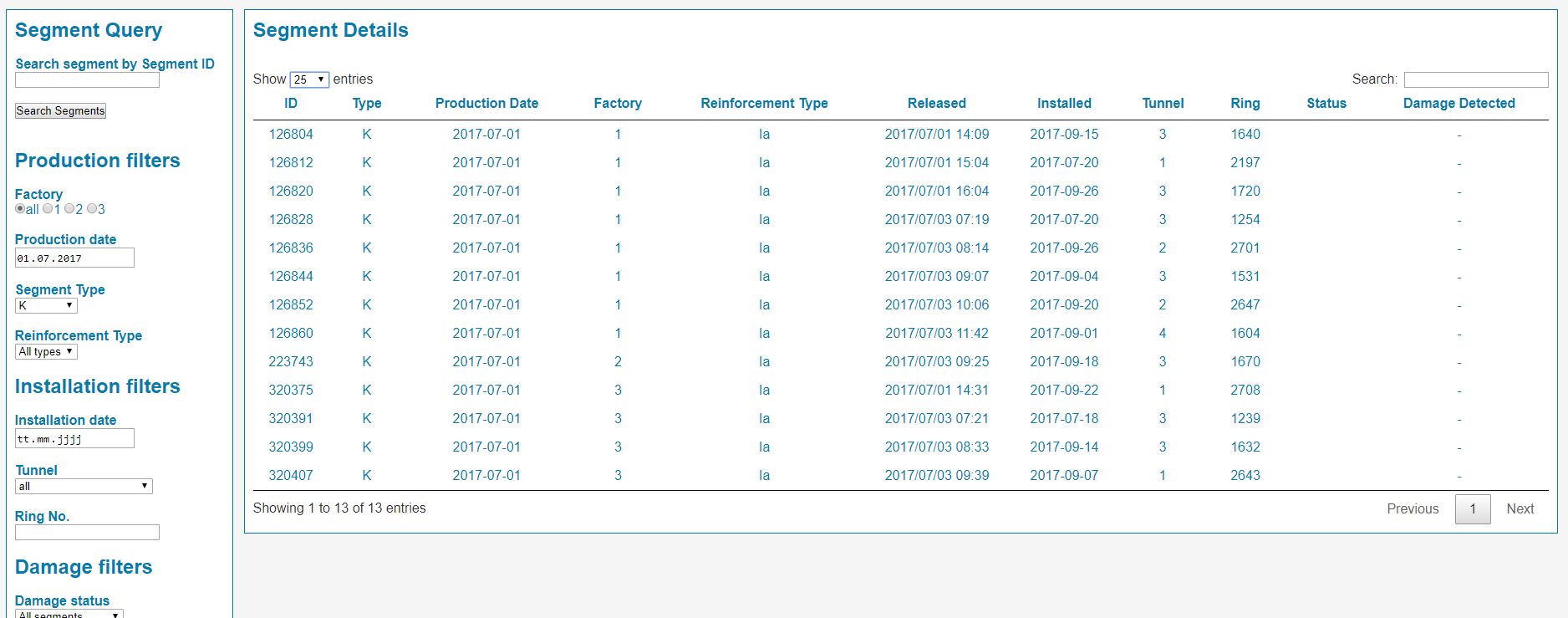

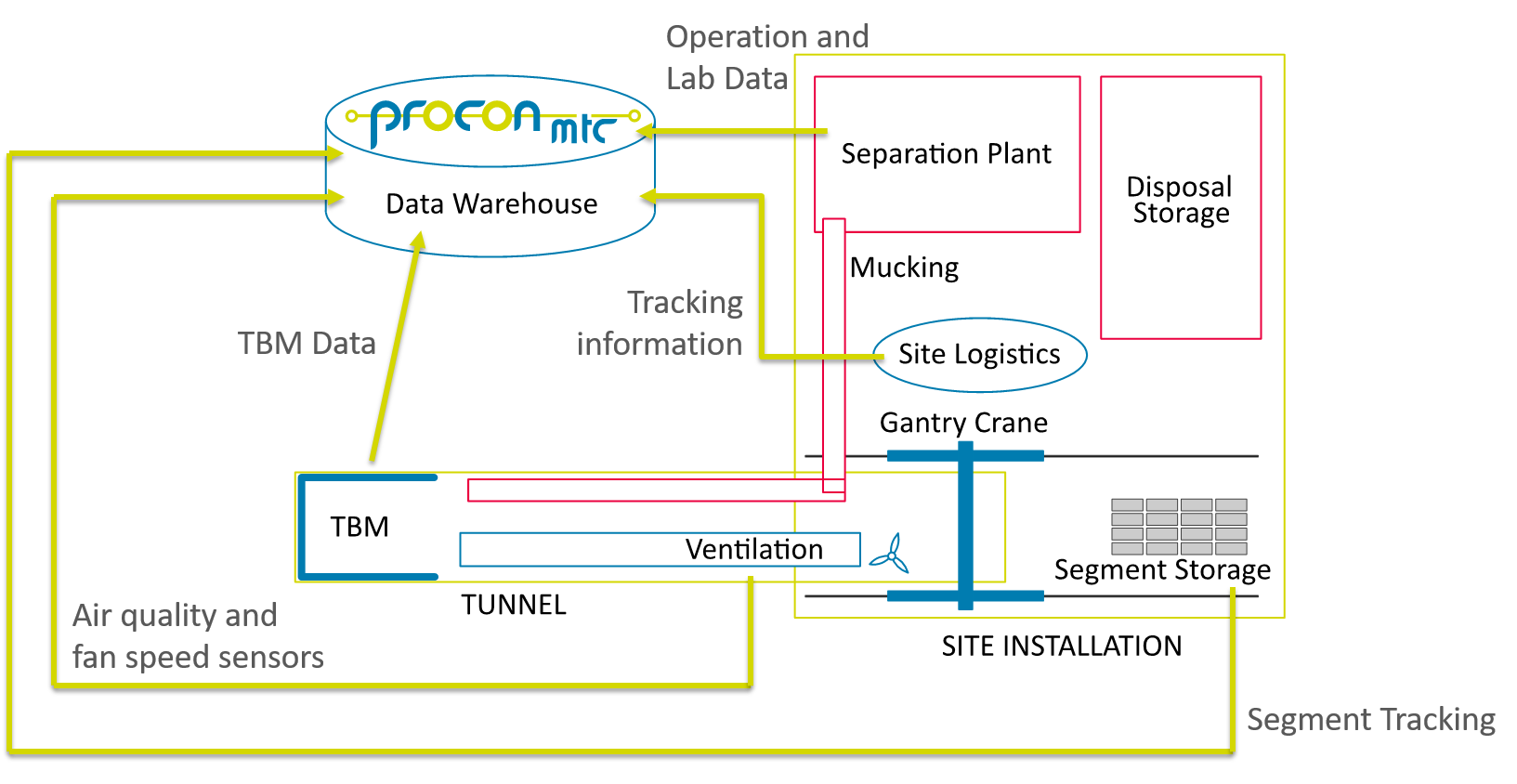

Segment Tracking

Segment Tracking describes the consistent tracking of produced

segments throughout their life cycle. This process includes the

production of the segments, their temporary storage on the

construction site, their installation as part of a tunnel ring

and their health status both during construction and operation of

the tunnel. The segments are tracked by applying labels with

codes on each segment.

Maidl Tunnelconsultants offer segment

tracking services in cooperation with a well-experienced partner

company, who provides the workflow implementation as well as all

required hardware including handheld devices for entering the

current information of the corresponding segments and a server

which stores all the collected information and transfers it to

the PROCON server. Thus, segment tracking information is

available and accessible through PROCON at any time.

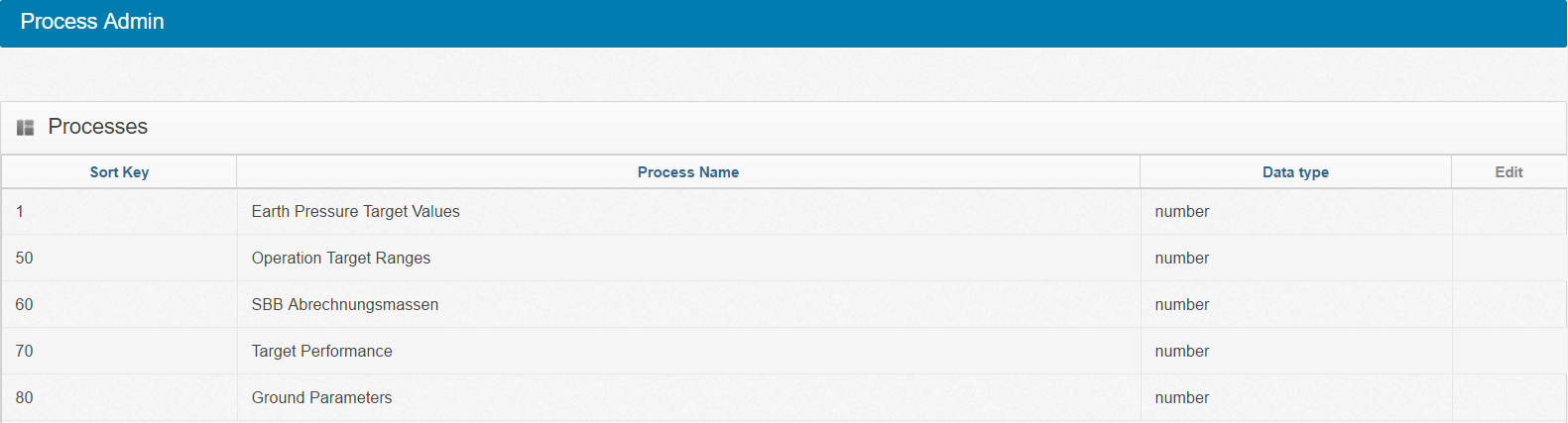

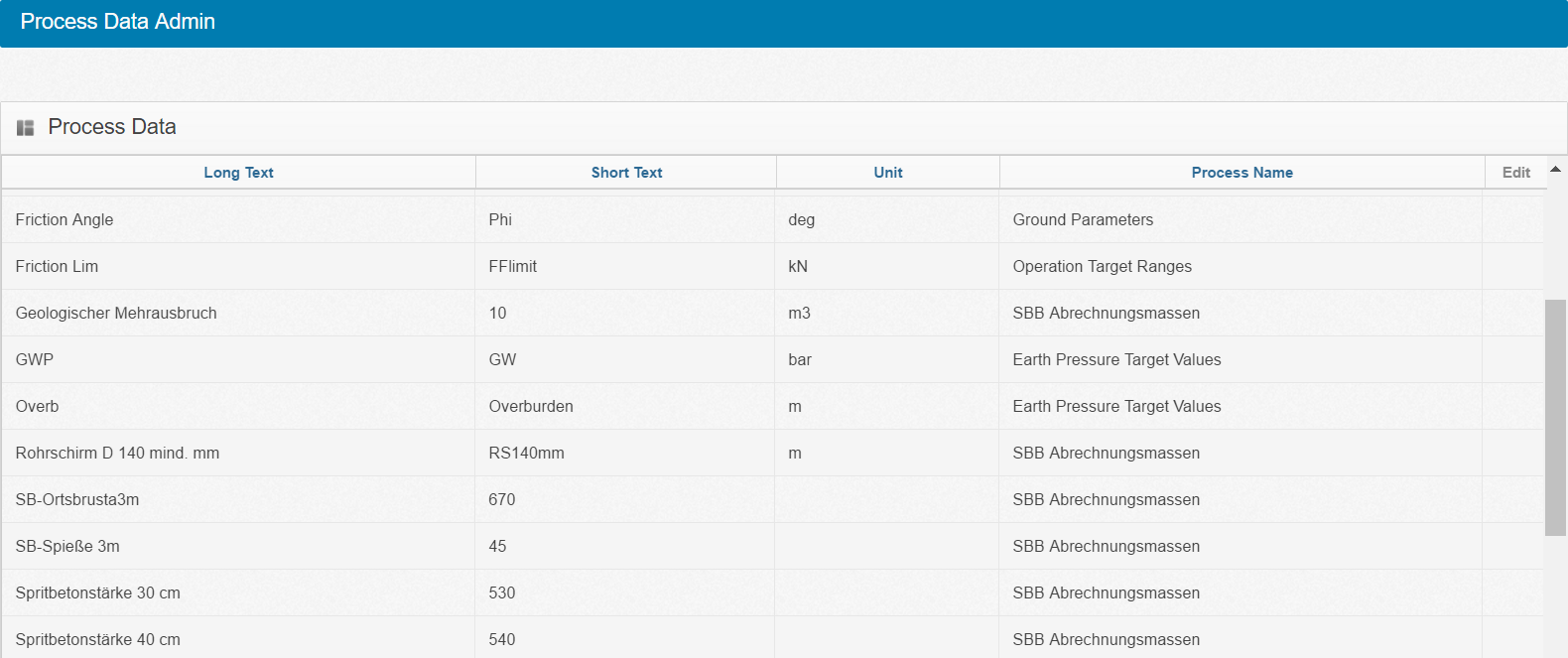

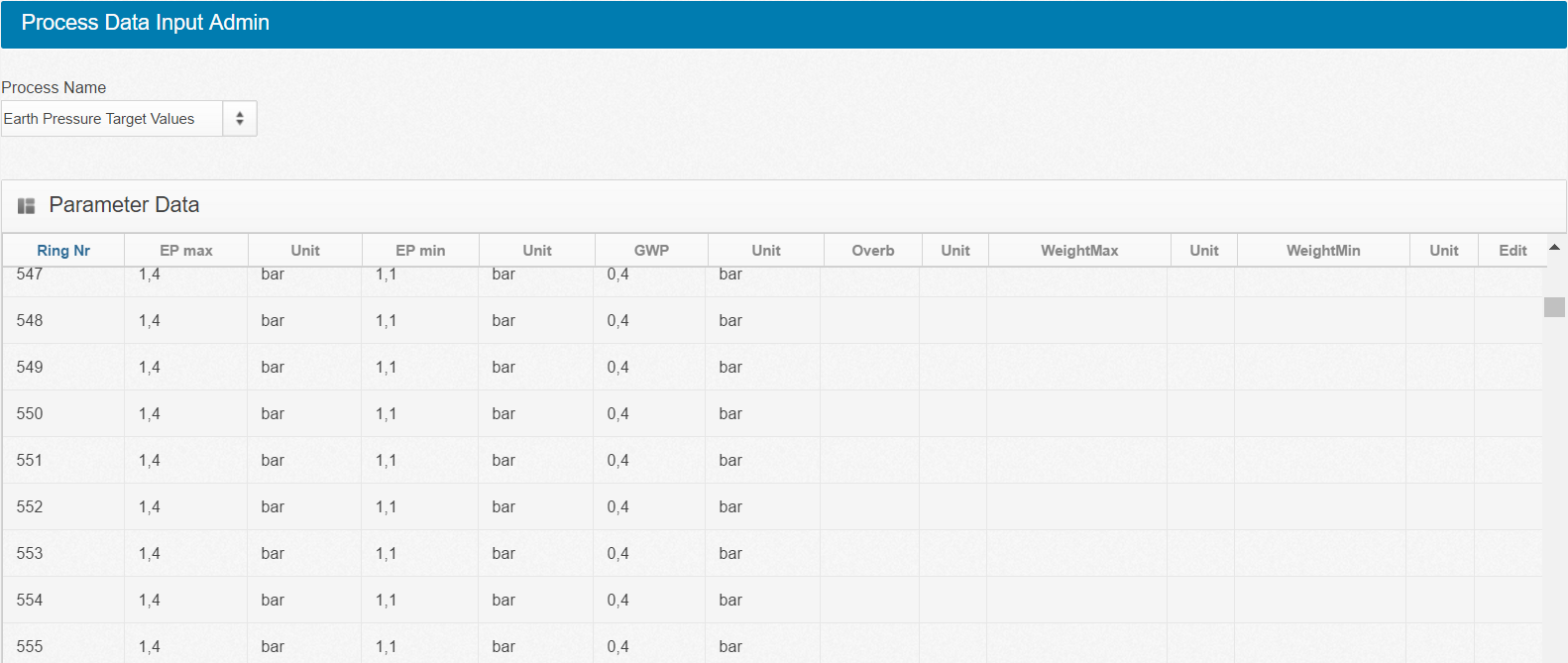

Ring-based information

In many cases, you may want to add location-based and

process-related additional information. These can be (ranges of)

target values for operational parameters such as the support

pressures. But also external measurements and evaluations such as

ground water levels, information on site logistics, or ground

conditions can be easily acquired on a by-ring basis.

PROCON II enables you to add this data in an arbitrary structure

by means of user-defined processes and definition of respective

data types. These data can be arbitrarily visualized and

combined with machine and monitoring data on Procon's dashboards.

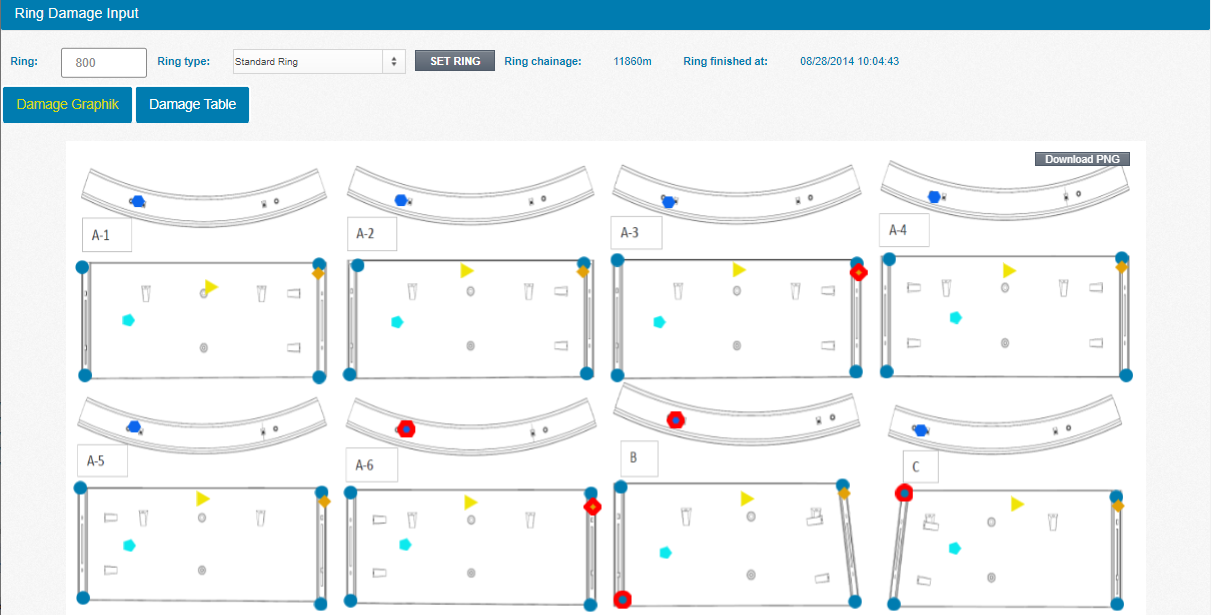

Damage of lining segments is not only possible during production

or in the storage, but also during transport and installation in

the tunnel. It is crucial for quality control to securely

document all damages and to track repair works.

PROCON II

includes an intuitive tool to enter and manage ring damages. Additionally, the

entered damages can be summarized in a PDF report for further

documentation.

Mobile View

Often you are on the move and you have no possibilities to monitor the current status of the project at a computer. Therefore, PROCON II offers a mobile version which can access customized dashboards via smartphone or tablet to monitor different aspects of the project to quickly react in case of problems. You can easily reach the mobile version using the browser of your device and the known URL.

Integration with BIM

BIM can be employed at an early stage of the tunnel project and used already to advantage in the design and construction phases. The key components of these models can be linked to each other by means of a common location and time reference framework.

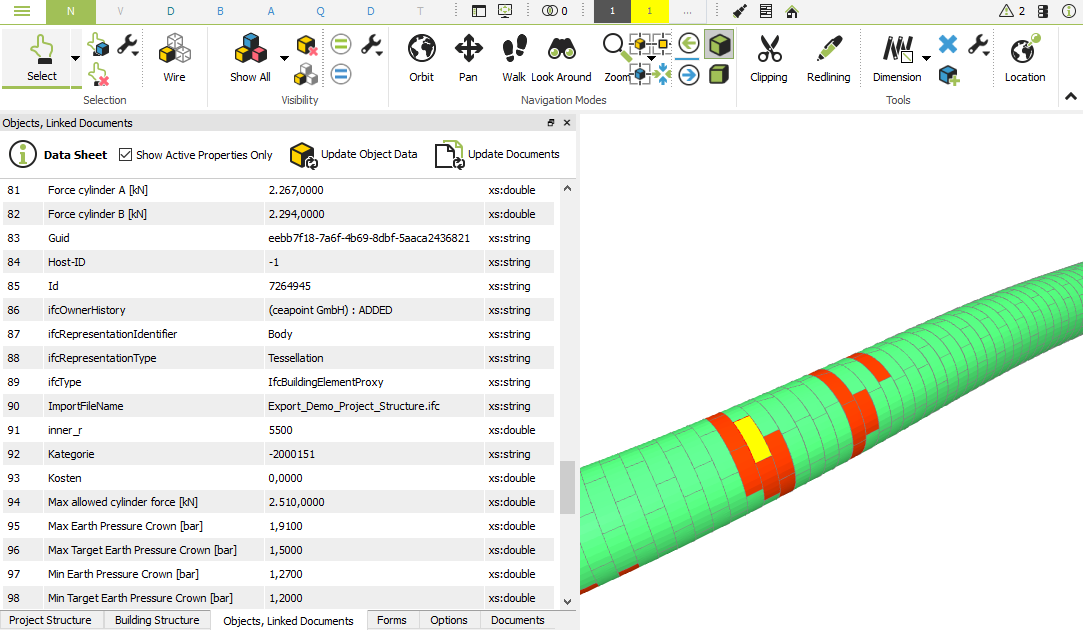

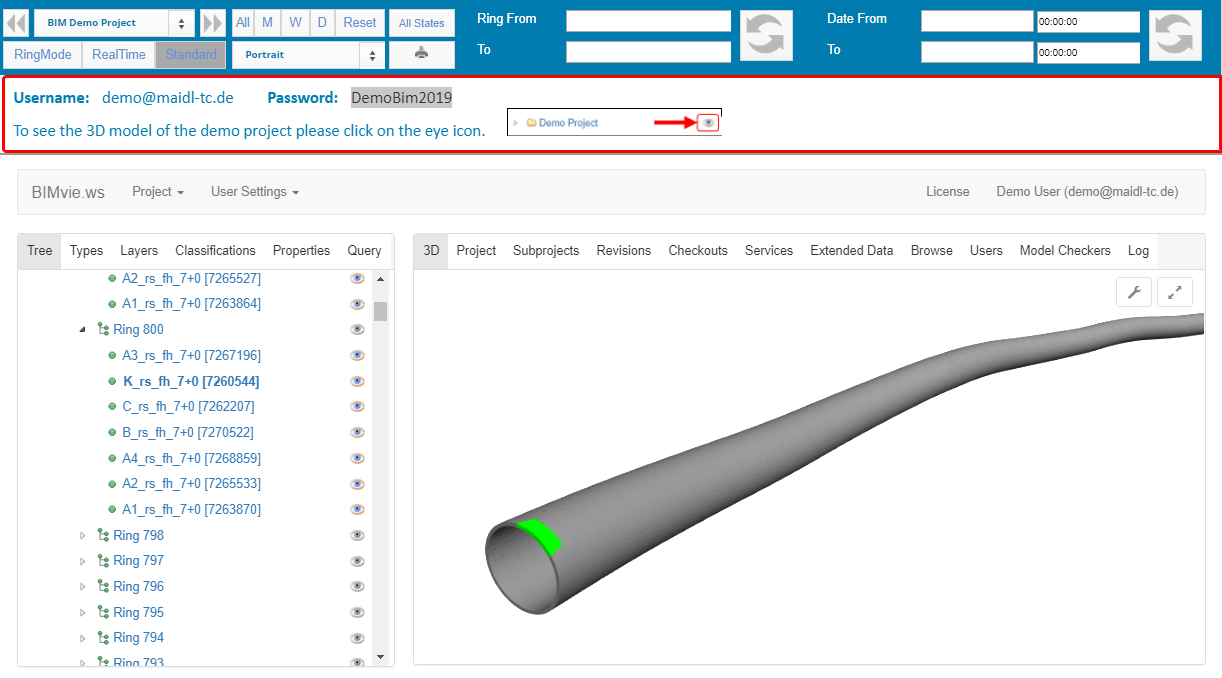

3D tunnel model

The tunnel model consists of the individual segmental linings representing the tunnel tubes. Each tunnel tube contains a number of rings consisting of a defined number of individual segments. Each digital segment has assigned various information from the start like its segment type or its ring number. During the tunnel advance, the information of the segments increases steadily by the incorporation of data from segment tracking and quality management, document linkage or highlighting of the TBM data history (e.g. thrust forces). An easily navigable visualization of the segmented lining allows a quick data identification, problem evaluation and overview of the projects progress.

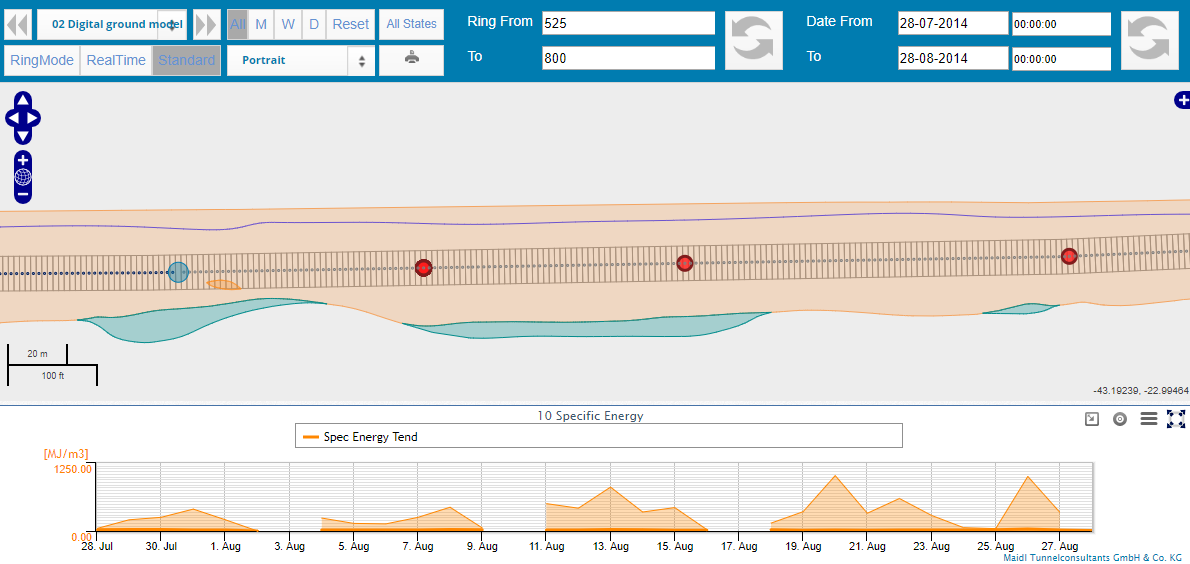

3D ground model

The purpose of a digital ground model is to provide information

from geotechnical investigation and geological expertise to all

project stakeholders in a computer-readable form.

Incorporating

a 3D ground model into the day-to-day project assessment provides

target-actual comparisons of ground conditions and disposal

masses, the verification of operation parameters and consumption

records as well as conservation of evidence.

The ground

model consists of numerous closed shells representing the

individual ground layers. Each layer has assigned its geological

properties. The volume of the 3D tunnel model is cut out from the

3D ground model. Along its alignment, the tunnel volume is

intersected with the digital ground model to create a digital 3D

tunnel model with areas of similar geotechnical properties.