The management of cutter tools is very important especially when

excavating in hard rock. The wear of the individual cutter tools

must be documented to prevent the tunneling machine from being

damaged due to worn-out tools. In Procon II, the individual tools

can be registered and maintained. Data can be entered based on

interventions which represents an event when the cutter tools are

checked for their current wear and changed, if required. Types of

cutting tools like disks, scrapers and buckets are distinguished

in the system and can be managed in respective user interfaces.

The entered intervention data can be displayed using Procon's

chart and dashboard configurators. Here, the tool consumption can

be correlated with machine data and geology information. Thus,

evaluations can be performed of the required tools in context of

the excavated ground. Following the identification of those wear

mechanisms, the prediction of the tool service life can be

improved and maintenance intervals can be optimized, reducing the

risk of unplanned standstills.

Correlating maintenance logs with

the digital ground model, data mining and data analysis tools

can be further employed to detect the influence of certain

ground properties, types of tools and driving parameters on

the tool wear. In this context, the number of changed tools of

different cutter types can be combined in one chart,

represented in different compressions like per ring, per day

or per week. This data can be arranged on a dashboard along

with data which influences the tool abrasion like the geology

or the thrust force. Based on this assembling of data the

advance can be evaluated and informed decisions can be made to

improve the excavation process.

The condition of the installed cutter tools is visually provided.

The current wear of the installed tools is represented by different

colors. Additionally, those tracks are highlighted on which a tool

has been exchanged, refurnished or switched. When displaying the

tracks of the discs an overview of the number of already changed

tools is shown on the right of the cutter image.

The

status of the tool condition can be presented for each

intervention. Furthermore, by selecting a specific track the

history of this track is provided in a table beneath the cutter

image.

All documented interventions are shown in a list with shortcuts to

their containing data. The interventions can be filtered by several

criteria to easily identify the required intervention. An

intervention can be exported to a customized PDF report for a

holistic documentation of the intervention.

This list can

also easily be added to a dashboard to generate a custom software

structure.

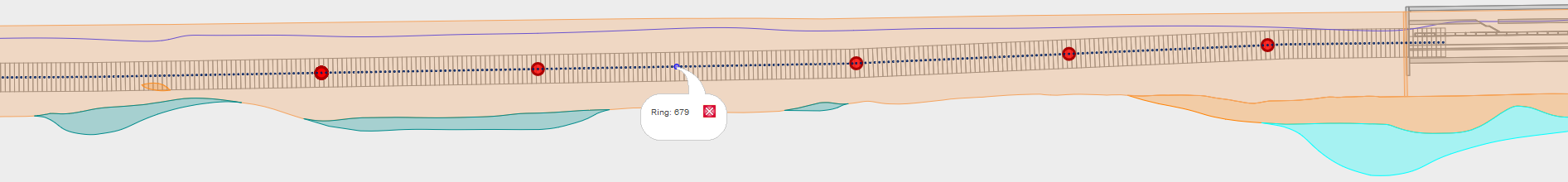

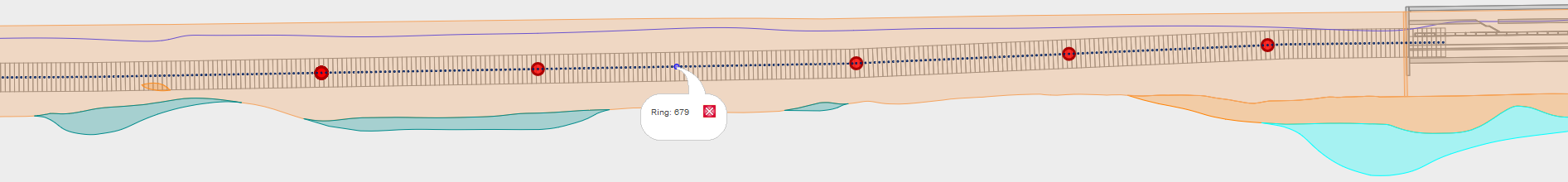

For entering a new tool change, an

intervention either has to be created or an existing one

edited. Each intervention is assigned to a ring during which

it was performed.

When a tool change or another

action on a tool shall be documented, the tool has to be

selected and the information can be assigned. In addition to

usual information like the current wear of the tool also

the reason for a tool change the so called wear picture can be specified.

When you open the page in the demo project, please select an

intervention (under the headline of "Edit Intervention") to

see some data.

For the documentation of the repair of the disassembeled tools,

PROCON provides a page to enter the data gathered during the repair

in the workshop. Based on this data, a PDF report can be generated

fow a holistic documentation.

In a pop-up a listed

overview is provided over the available refurbishment parts.