An interactive module for shift protocols extends the list of

optional features of PROCON. Extracting periods of advance, ring

building and standstill automatically from the machine data,

these time intervals are displayed using a Gantt chart

visualization for each shift.

Shift reporting represents

an essential element of the documentation of a tunneling project.

All actions are documented and can be evaluated as well as

exported. In Procon II, multiple types of shifts per day can be

generated like a morning, day and late shift. The key processes

like advance and ring build are automatically retrieved from the

machine data and assigned to each shift. The reason for each

downtime slot needs to be specified by the user. Here, the

catalog of downtimes is specified according to each project's

requirements. Based on the documented downtime reasons,

evaluations can be performed based on which the process can be

optimized.

For detail evaluations, additional filters on

specific shifts or staff members can be used, hence allowing for

an assessment of reasons for performance differences among the

shifts or to identify specific parameters that correlate with the

performance. The integrative nature of the data warehouse and the

unified temporal and spatial reference system helps identifying

previously unknown interactions and hidden mechanisms in the

process.

After logging in to PROCON, the start page of the project shows the user the current status of the project.

On top of the page, additional blue buttons lead to further content. On the one hand a map representation of the project and on the other hand a collection of dashboards with important content.

On the left side of the current status page, the project status is visualized based on the current chainage location of the machine.

Additionally, current project information like the current ring, status and production times are show.

Furthermore, information is provided on the number of built rings for the last shifts, day, week, month or year.

On the right side, 3 charts are provided visualizing the number of built rings of the projects for different time intervals.

By clicking on a column of an upper chart, the lower charts adapt their time range to the selected time interval.

The time interval can also be adapted by applying the buttons on top of the charts.

Evaluate the downtime distribution and analyze the reasons for

performance issues using different visualizations like pie charts

or bar charts. In those charts, either specific codes can be

captured or a whole group code. In this example, groups of codes

are selected.

The x-axis of the downtime bar charts can be

selected as required. For example, the downtimes can be evaluated

by ring, by day or by week.

Combining this information,

all processes in excavation can be analyzed regarding their time

and cost structure. Here, all information stored in PROCON can be

employed, like, e.g. geological information or machine data.

The planned processes and downtime

durations can also be visualized in usual charts.

Additionally, other pages, e.g. of Procon, can be integrated

into a dashboard for operation. Here, the page for data input

is integrated into the dasboard so that you can easily enter

the specific downtime reasons in context of the overall

advance progress.

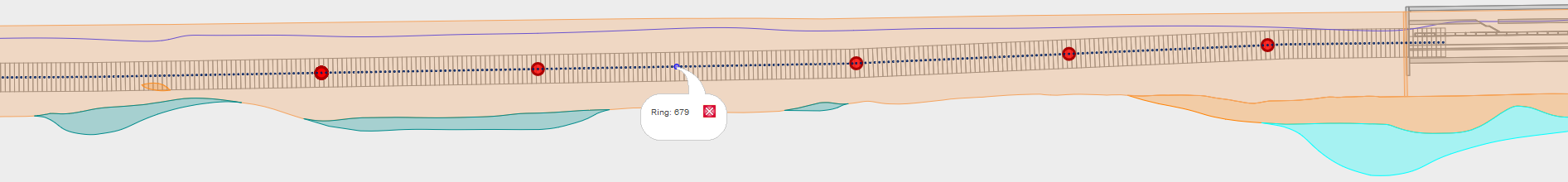

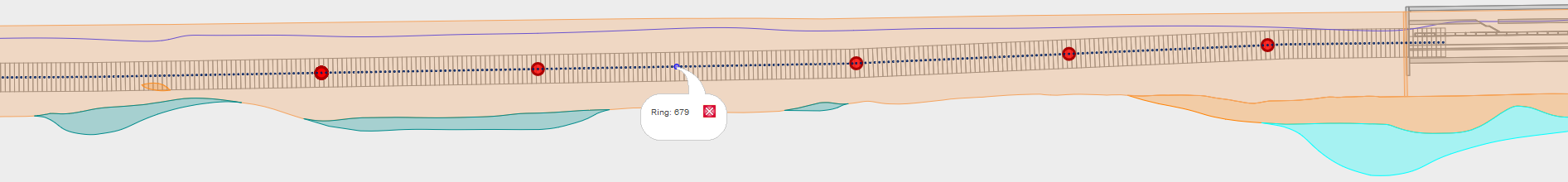

The individual downtimes for each shift

can be entered in a simple mask. A gantt chart on the top of

the page shows the main processes advance, ring build and

downtime along with already configured downtimes. The share of

each main process is shown in an adjacent pie chart. Each

process is assigned to a ring number that serves as location

reference and helps analyzing the downtimes for each ring

separately.

The entered downtimes can either be critical

or non-critical. Non-critical downtimes can overlap other

critical tasks whereas critical process and downtimes are not

allowed to overlap.

If required, those downtimes which

have not been assigned to a downtime category (e.g. because

they are too small), can be automatically be assigned to an

uncategorized downtime category to ensure that all downtimes

are captured. Additionally, many smaller downtimes can be

merged to one bigger one, if this is required to document the

shift.

Important: To see

entered downtime on the demo page, please select either a ring

(range: 525 - 800) or a date in the "Shift Selection" (range:

27.07.2014 - 27.08.2014), a shift type and, optionally, a time

restriction. Next, click on the "refresh" link on the right.