Damage of lining segments is not only possible during production

or in the storage, but also during transport and installation in

the tunnel. It is crucial for quality control to securely

document all damages and to track repair works.

PROCON II

includes an intuitive tool to enter and manage ring damages. Additionally, the

entered damages can be summarized in a PDF report for further

documentation.

Damage of lining segments is not only

possible during production or in the storage, but also during

transport and installation in the tunnel. It is crucial for

quality control to securely document all damages and to track

repair works.

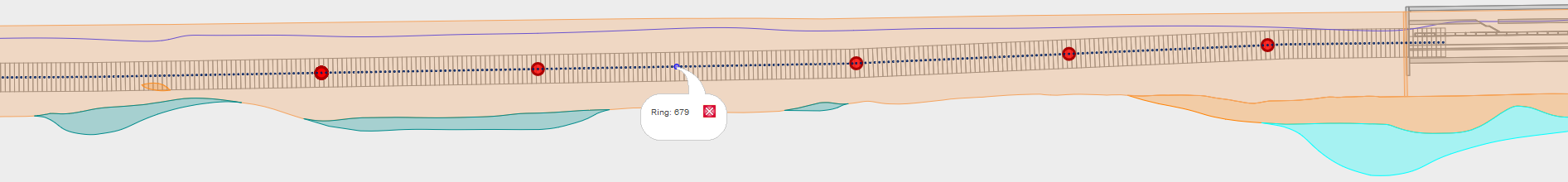

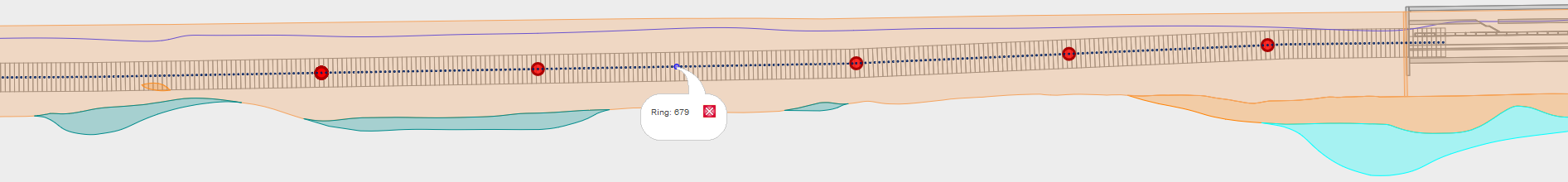

PROCON II provides an in-built service to

easily track damaged segments. By means of a dedicated input

panel in PROCON II or via an interactive graphical representation

of rings and their segments, damages can be classified and

documented. Their repair status is tracked along the complete

workflow.

All information gathered in

the segment damage tracking can be exported in terms of PDF reports.

PROCON's typical visualisation and analysis tools

are available for segment damages, helping to chase damage

patterns or quality issues. Evaluations can be generated, for example, based on the ring type, segment, damage type or thrust jack position.

The generated evaluation charts can be combined on dashboards with geological data, TBM, data, etc. to easily find correlations between the data sources.